How to Start a Nail Manufacturing Business with a Nail Making Machine

Category:News

Author:

Source:

Add time:2025-05-07 11:59

Starting a nail manufacturing business can be a profitable venture, especially in regions like South America, the Middle East, Southeast Asia, and Africa, where rapid urbanization and infrastructure development drive demand for construction materials. However, success depends on understanding local market needs, choosing the right equipment, and addressing challenges unique to emerging economies.

In this guide, we’ll walk you through the steps to launch a nail production business, focusing on cost-effective strategies and solutions tailored to markets with limited resources. We’ll also highlight how the DAPU Nail Making Machine can simplify your journey from startup to profitability.

Step 1: Market Research and Business Plan

Before investing in machinery, analyze your target market:

Key Questions to Answer:

Who are your customers?

Construction firms, hardware stores, or wholesalers?

What nail types are in demand?

Common nails, roofing nails, or concrete nails? (e.g., roofing nails are critical in Middle Eastern climates.)

What pricing works locally?

In regions like Africa or Southeast Asia, affordability often beats premium quality.

Regional Insights:

South America: High demand for nails in informal housing projects.

Middle East: Corrosion-resistant nails for coastal or desert environments.

Africa: Low-cost nails for rural infrastructure and solar installations.

Southeast Asia: Recycled-material nails to reduce costs.

Tip: Partner with local construction associations or trade groups to validate demand.

Step 2: Choose the Right Nail Making Machine

Your machine is the heart of your business. Prioritize models that solve emerging market challenges:

Critical Features to Look For:

Power Adaptability:

In areas with unstable grids (e.g., rural Africa), opt for low-power machines compatible with generators or solar systems.

The DAPU Nail Making Machine uses only 7.5 kW and works reliably in low-voltage conditions.

Material Flexibility:

Can the machine handle recycled steel or varying wire thicknesses?

DAPU’s model supports wire diameters from 1.2mm to 5.0mm, ideal for regions with inconsistent raw material supplies.

Ease of Use:

Avoid complex machines requiring skilled operators. Look for intuitive controls and automated functions.

DAPU’s touchscreen interface and error-detection system reduce training time and downtime.

Durability:

Choose rust-resistant, heavy-duty frames for humid or dusty environments (e.g., coastal West Africa or the Middle East).

Affordable Maintenance:

Machines with easily replaceable parts save long-term costs.

Step 3: Source Raw Materials

Steel wire is your primary input. In emerging markets:

Local Suppliers: Partner with steel mills or recycling centers (common in Southeast Asia).

Cost-Saving Tip: Use recycled wire, but ensure it meets quality standards to avoid machine jams.

Storage: Keep wire coils dry to prevent rust, especially in humid climates.

Step 4: Set Up Your Workspace

Location Requirements:

Space: A small workshop (20–30 sqm) is sufficient for a single machine.

Power: Ensure access to 3-phase electricity or invest in a solar/generator hybrid system.

Ventilation: Critical in hot climates to protect both workers and machinery.

Labor:

Hire 1–2 workers for basic operations. Focus on training them to handle simple tasks like loading wire and quality checks.

Step 5: Production Process

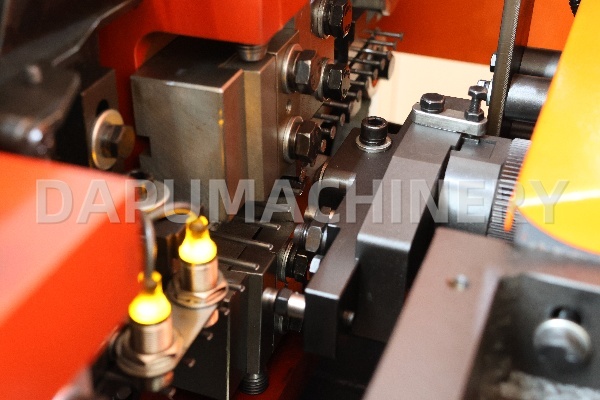

Here’s how a nail making machine like DAPU’s transforms wire into nails:

Wire Feeding: Load the coil into the machine.

Cutting: The wire is cut to the desired nail length.

Head Formation: A hammer molds one end into a nail head.

Pointing: The other end is sharpened.

Finishing: Optional coating or polishing for corrosion resistance.

Pro Tip: Start with common nail sizes (e.g., 1–3 inches) to cater to broad demand.

Step 6: Quality Control

Poor-quality nails harm your reputation. Implement checks like:

Sample Testing: Measure nail length, head strength, and tip sharpness hourly.

Rust Prevention: Use galvanized wire or apply coatings if selling to humid regions.

Step 7: Pricing and Marketing

Pricing Strategy:

Cost-Plus Pricing: Calculate production costs (materials, power, labor) and add a 20–30% margin.

Competitor Benchmarking: In price-sensitive markets like Africa, stay slightly below imported nail prices.

Marketing Channels:

Local Hardware Stores: Offer bulk discounts to retailers.

Construction Sites: Directly supply contractors in fast-growing cities (e.g., Lagos or Jakarta).

Social Media: Use Facebook or WhatsApp to reach small builders in rural areas.

Step 8: Overcome Common Challenges

1. Power Outages:

Solution: Use the DAPU machine with a solar inverter or diesel generator.

2. Material Shortages:

Solution: Build relationships with multiple suppliers to avoid delays.

3. Maintenance Issues:

Solution: Follow DAPU’s maintenance guide—lubricate parts weekly and clean debris daily.

Why the DAPU Nail Making Machine is Ideal for Startups

The DAPU Automatic Nail Making Machine is designed to help small businesses thrive in tough conditions:

Low Operating Costs: Energy-efficient design cuts power bills.

Minimal Training: Farmers in Kenya and Vietnam have successfully operated it with basic guidance.

Built to Last: Stainless steel components resist corrosion in salty or humid air.

Local Support: DAPU partners with regional distributors for spare parts and repairs.

Technical Specs:

Production Speed: 200–400 nails/minute

Power: 7.5 kW

Nail Length: 10mm–150mm

Weight: 1,500 kg

Case Study: A Success Story from Ghana

A startup in Accra used the DAPU machine to produce roofing nails from recycled wire. Despite frequent power cuts, they powered the machine with solar panels and captured 15% of the local market within six months. Their key to success? Affordable pricing and reliable nail quality.

Final Tips for Success

Start Small: Begin with one machine and expand as demand grows.

Focus on Relationships: Build trust with local suppliers and buyers.

Monitor Trends: Adapt to new nail types (e.g., eco-friendly coatings) as markets evolve.

Conclusion

Launching a nail manufacturing business in emerging markets is challenging but rewarding. By choosing a robust, adaptable machine like the DAPU Nail Making Machine, you’ll address critical pain points—power instability, high costs, and harsh environments—while delivering products your community needs. With careful planning and the right equipment, you can turn raw steel into a steady stream of income.

Ready to start your journey? Visit DAPU Machinery to explore financing options and get personalized support for your nail production business.

Recommend News