Rebar Stirrup Bending Machine DP-ZGW

Key words:

Classification:

Product Description

|

| Description: |

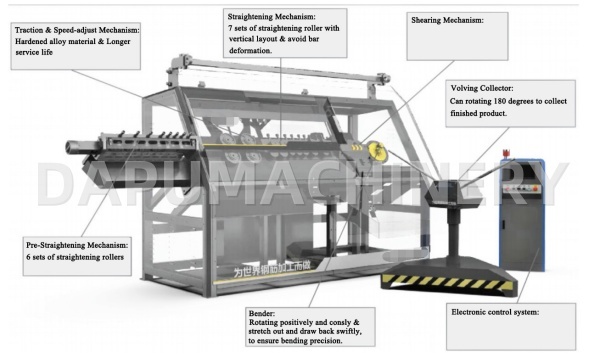

DAPU Stirrup Bending Machine DP-ZGW Overview

-

Pay-off Mechanism: Two sets of horizontal racks, each with a 2-ton capacity, automatically feed steel bars to the machine.

-

Wire Management Basket: Prevents wire tangling with an effective management device.

-

Straightening Mechanism: Dual straighteners (horizontal and vertical) allow independent adjustment for double-line steel bars.

-

Shearing Mechanism: Features a motor-driven fixed and moving blade for efficient, low-maintenance cutting.

-

Electronic Control System: Industrial CNC control with high precision and a user-friendly touch screen for designing stirrups and contour bars of any shape up to 32 corners.

DAPU's Stirrup Bending Machine DP-ZGW combines advanced technology with reliable performance, delivering precise bar bending and cutting for high-quality results.

| Technical Parameter: |

| Model | ZGW-12C | ZGW-12F | ZGW-16B |

| Wire diameter range (Single line) | Φ4-Φ12mm | Φ6-Φ12mm | Φ6-Φ16mm |

| Wire diameter range (Double line) | Φ4-Φ10mm | Φ6-Φ10mm | Φ6-Φ12mm |

| Traction speed | Max.80-110m/min | Max.80-110m/min | Max.80-120m/min |

| Bending speed | 1100°/sec | 1150°/sec | 1150°/sec |

| Angle error | ±1° | ±1° | ±1° |

| Length error | ±1mm | ±1mm | ±1mm |

| Wire receiving shelf length | Max.12m | Max.12m | |

| Min. bending length | 80mm | 50mm | 100mm |

| Bending angle (2 direction) | Max.180° | Max.180° | Max.180° |

| Air pressure | ≥0.6Mpa | ≥0.7Mpa | ≥0.8Mpa |

| Total Power | 33kw | 33kw | 34kw |

| Electricity consumption | 6-7kw/h | 7kw/h | 7kw/h |

| Optional Equipment: |

|

|

|

| Unwinding Machine | Flattening Machine | Leveling, Slitting and Cutting Machine |

| Finished Product & Application: |

It is widely used in construction, hardware, window and door, machine protection etc.

|

|

|

| Machine operation display: |

FAQ

1. Can the DAPU CNC Stirrup Bender handle high-strength rebar like Grade 60 or HRB500?

Yes. Our machines are engineered with high-torque servo motors and reinforced feeding rollers specifically designed to process high-tensile rebar. Whether you are using cold-rolled or hot-rolled smooth or ribbed steel, the system maintains consistent bending torque without motor overheating.

2. What is the real-world production capacity in terms of pieces per hour?

Efficiency depends on the stirrup size and wire diameter. On average, our high-speed models can produce 1,800 to 2,200 stirrups per hour. For smaller sizes, the dual-wire feeding system allows the machine to process two wires simultaneously, effectively doubling your output compared to traditional single-wire machines.

3. How does the machine ensure the precision of the bending angle and hook length?

Precision is controlled by a closed-loop CNC system with high-resolution encoders. This ensures a bending tolerance of within ±1° and a length tolerance of ±1mm. This level of accuracy is critical for meeting international building codes and ensuring smooth assembly in rebar cages.

4. Is it difficult for a local operator in Southeast Asia or Africa to program the shapes?

Not at all. We use an Industrial Touch Screen PLC with an intuitive graphical interface. The system comes pre-loaded with over 500 standard geometric shapes. An operator only needs to select the shape and input the dimensions. No complex coding knowledge is required.

5. What are the key wear parts, and how often do they need replacement?

The primary wear parts are the cutting blades, bending pins, and feeding rollers. Using high-quality alloy tool steel (H13 grade), our blades typically last for 30,000 to 50,000 cuts before requiring sharpening or replacement, ensuring minimal downtime in remote project sites.

6. How does the machine perform in areas with unstable voltage or high temperatures?

We equip our export-grade machines with independent electrical cabinets featuring forced-air cooling and high-quality Schneider/Siemens components. For regions with fluctuating power, we recommend a specialized stabilizer, but our systems are built with a ±10% voltage tolerance to ensure operational stability.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.