Leveling, Slitting and Cutting Machine

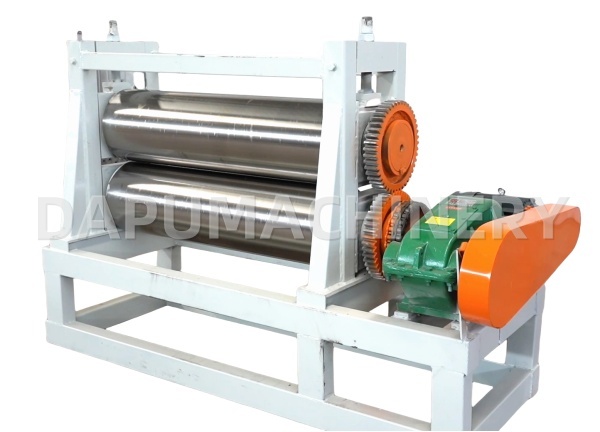

DP-25T Expanded Metal Mesh Machine

DP-25T Expanded Metal Mesh Machine by DAPU — Engineered for high efficiency and precision, ideal for processing thin materials (0.2–1.5mm) with a maximum width of 1500mm, easily adaptable to various raw materials. The 30mm LWD mesh openings are cleanly formed, and the adjustable feeding distance (0–5mm) allows for quick and easy spec changes. With a punching speed of 260 strokes per minute, it ensures high output and productivity. Powered by a 5.5KW motor, it offers strong performance while saving energy. Comes with a full installation video and lifetime online tech support. Trusted by customers in over 100 countries, DAPU delivers quality you can count on. Choose DP-25T now and start producing premium expanded metal mesh!

Key words:

Classification:

Product Description

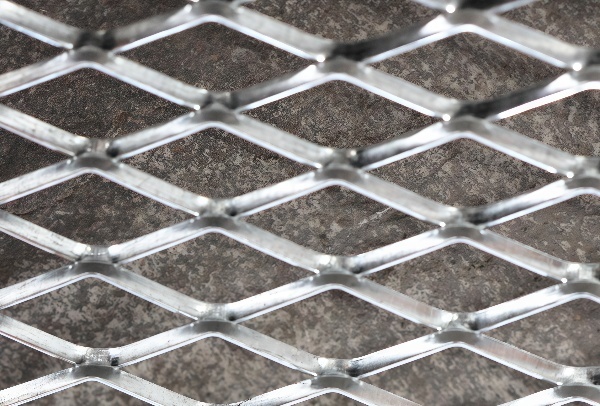

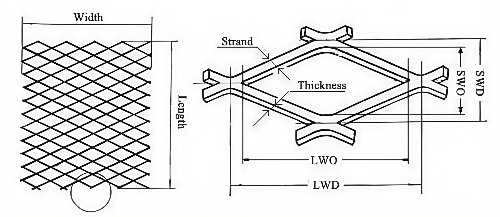

Expanded metal mesh machine can produce expanded metal mesh which is widely used in construction, hardware, window and door, machine protection etc. It can be produced width max.1200mm and thickness of metal sheet max.1.5mm. The material for expanded metal mesh can be low carbon steel plate, stainless steel plate, aluminum plate, copper plate and so on.

Technical Parameter

| Model | DP-25T |

| Material thickness | 0.2-1.5mm |

| Material max. width | 1500mm |

| LWD of mesh opening | 30mm |

| Distance of feed | 0-5mm |

| Speed (R/m) | 260 |

| Motor | 5.5KW |

| Net weight | 3.3T |

Optional Equipment

Finished Product

It is widely used in construction, hardware, window and door, machine protection etc.

Order delivery

Other models

FAQ

1. What is the maximum speed (SPM) and typical material thickness range for the DP-25T?

The DP-25T is a high-speed machine designed for efficiency. It can reach speeds of up to 300 strokes per minute (SPM). It is ideally suited for materials ranging from 0.3 mm to 2.0 mm thickness, focusing on aluminum, fine mesh, and plaster mesh applications.

2. The 25T is used for fine mesh. How does DAPU ensure the high precision needed for small LWD/SWD cuts?

Precision comes from the machine's lightweight yet rigid design and advanced feeding mechanism. The DP-25T features a servo-motorized feeding system with a micron-level encoder, which guarantees a high degree of feeding accuracy at high speed, crucial for small, consistent mesh openings.

3. Is the DP-25T suitable for manufacturing delicate decorative mesh or filtration mesh?

Absolutely. Its high speed and precision make it perfect for decorative items (e.g., ceilings, facades) and filtration applications. We can provide specialized cutting blades that minimize burrs and deformation, ensuring the highest surface finish required for aesthetic products.

4. What kind of raw material feed system is recommended for the DP-25T's high-speed operation?

We recommend using a Single-Arm Uncoiler or a Light-Duty Motorized Decoiler paired with a quick-response tension control system. This ensures the material feeds smoothly and consistently at the high SPM required by the 25T, preventing material tearing or jamming.

5. Since the 25T runs fast, what are the maintenance requirements for the lubrication system?

The 25T uses a simplified, yet highly effective centralized automatic lubrication system. Regular checks of the oil level (daily) and a system flush/oil change (every 6 months) are typically sufficient, making maintenance straightforward and minimizing downtime.

6. Can the DP-25T handle pre-painted galvanized (PPGI) steel for use in ceiling applications?

Yes. For pre-painted materials, we install custom protective guides and soft-contact rollers within the machine to prevent scratching or damaging the painted surface during the expansion process, preserving the aesthetic quality of the finished product.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.