Razor Wire Machine

Stop importing expensive razor wire and start your own high-profit production today. Engineered for the rugged demands of emerging security markets, the DAPU Razor Wire Machine combines high-speed precision punching with a fully automated wire-wrapping system. Whether you are processing galvanized or stainless steel, our machine ensures sharp, consistent barbs and a secure, tight wrap every time.

Key words:

Classification:

Product Description

|

|

|

| Description: |

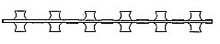

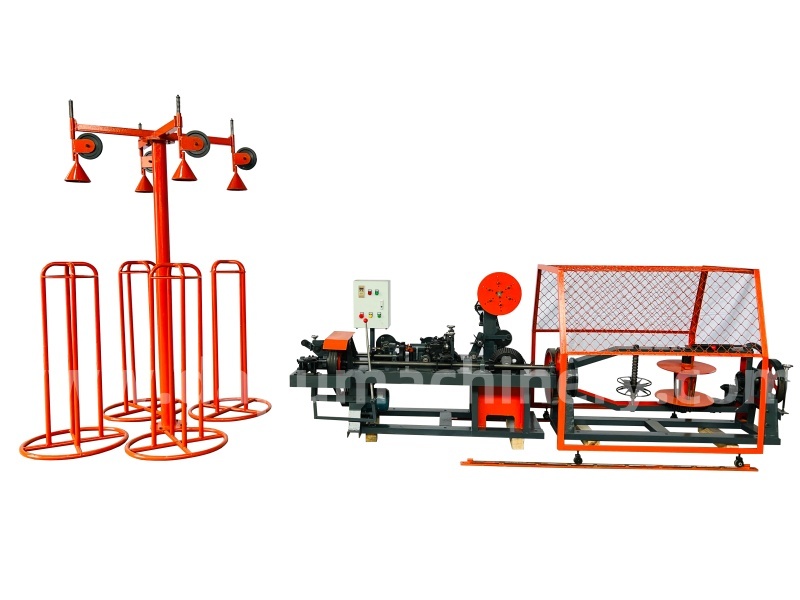

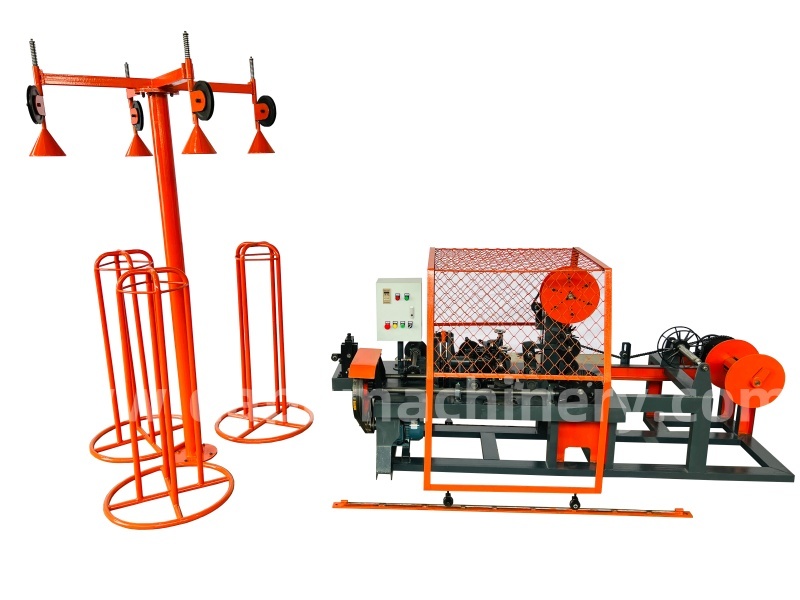

Razor barbed wire machine produce razor barbed wire,it include Razor Strips making Machine and Coiling machine. Razor barbed wire machine with five strips is light-style, easy to operate, high efficiency, can save 20% raw material. It is mainly consists of main machine which can produce the strip plate and coiling machine which can coil the wire into the strip plate. Mainly used in military facilities, communication stations, power distribution stations, border line of the prison, landfill, community protection, schools, factories, farms and other security isolation.

There are two steps in production process, and there are two different machines would finish all work. (Razor Strips making Machine, Coiling Machine)

Razor Strips making Machine: This Machine use to cut the steel strip, and make steel strip become razor shape. Different moulds can make different razor shape. Now we always use the model of 5 or 9 output Strips Type, comparing the old one strip mould these models are not only makes production high efficiency, but also can save materials.

Coiling Machine: Coiling Machine is used to coil the razor strip to the steel wire. And then wind up the Razor Barbed Wire to the wire spool.

| Technical Parameter: |

| Model | 25T | 40T | 63T | Coiling machine |

|---|---|---|---|---|

| Power | 2.2kw | 4kw | 5.5kw | 1.5kw |

| Producing speed | 70 times/min | 75 times/min | 120 times/min | 3-4 ton/8h |

| Pressure | 25 Ton | 40 Ton | 63 Ton | — |

| Material thickness and wire diameter | 0.5±0.05mm, according to your requirement | 2.5mm | ||

| Material of sheet | GI and stainless steel | GI wires | ||

| Voltage | 3 phase 380V/220V/440V/415V, 50HZ or 60HZ | |||

| Weight | 2200 kgs | 3300 kgs | 4500 kgs | 300 kgs |

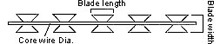

Mould Type:

| MOULD STYLE: | Barb Length | Barb Width | Barb Spacing | Illustration |

| R1 | 12±1mm | 13±1mm | 26±1mm |  |

| R2 | 12±1mm | 15±1mm | 26±1mm |  |

| R3 | 18±1mm | 15±1mm | 33±1mm |  |

| R4 | 22±1mm | 15±1mm | 34±1mm |  |

| R5 | 28±1mm | 15±1mm | 34±1mm |  |

| R6 | 30±1mm | 18±1mm | 34±1mm |  |

| R7 | 60±1mm | 32±1mm | 96±1mm |  |

| R8 | 65±1mm | 21±1mm | 100±1mm |  |

| Finished Products & Application: |

|

|

|

|

|

|

|

| Video: |

| Related Products: |

|

|

|

| CS-A Barbed Wire Machine | CS-B Barbed Wire Machine | CS-C Barbed Wire Machine |

FAQ

1. What is the maximum production speed for different razor types like BTO-22 or CBT-65?

Our high-speed punching unit operates at 200-300 strokes per minute. Depending on the blade profile, a single line can produce 200-300kg of finished razor wire per hour. This high throughput ensures you can fulfill large government or commercial security tenders ahead of schedule.

2. How does the machine ensure the steel strip is tightly wrapped around the core wire?

The DAPU machine features a multi-wheel compression wrapping system. This mechanism applies uniform pressure to ensure the razor strip "bites" into the high-tensile core wire, preventing it from sliding or loosening. A tight wrap is crucial for the structural integrity and lethal effectiveness of the finished concertina wire.

3. How long do the punching molds last, and is it difficult to switch between different blade shapes?

We use premium SKD11 alloy steel for our molds, which undergo specialized vacuum heat treatment. One set of molds can typically process 500-800 tons of steel strip before needing maintenance. The modular design allows for a quick mold changeover (approx. 1 hour), enabling you to switch between BTO-10, BTO-22, or CBT-65 profiles easily.

4. Can the machine handle stainless steel strips as easily as galvanized steel?

Yes. Our machines are built with a reinforced gantry frame and high-torque motors to handle the extra hardness of Stainless Steel 304 or 316. The punching pressure and feeding speed are adjustable via the PLC to ensure clean cuts and prevent material deformation regardless of the metal grade.

5. How much space and labor are required to run a complete razor wire production line?

A complete line (Punching + Coiling + Wrapping) is designed with a compact linear layout, requiring approximately 15m x 3m of space. Because the line is fully automated with sensor monitoring, one operator can easily manage 2-3 lines simultaneously, drastically reducing your monthly labor overhead.

6. Does the machine include a solution for packing and compressing the finished coils?

We offer an integrated concertina wire packing machine as a standard option. This unit compresses the finished razor wire coils into compact, uniform bundles, which can reduce your shipping and storage volume by up to 60%, making your product more competitive for export.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.