Touch screen control

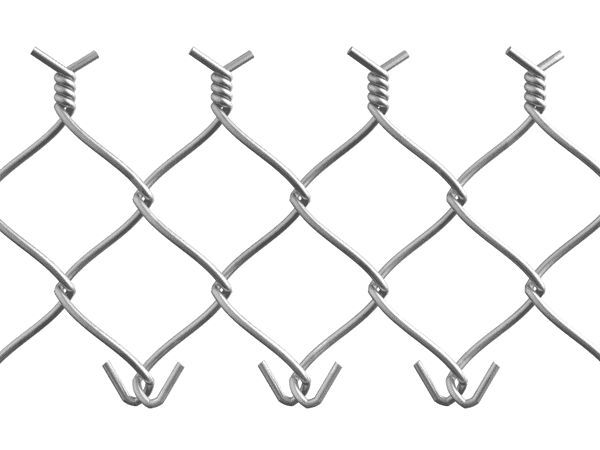

Economy Chain Link Fence Machine

The automatic chain link fence machine DP20-100 can use a wire with a diameter of 1.6-4mm, and the raw material tensile strength can be 350- 800MPA. Usage: Finished chain link fence is extensively used as fences for playgrounds and gardens, highways, railways, airports, ports, etc.

Key words:

Classification:

Product Description

Technical Parameters

Model | DP20/100,single wire |

Capacity | 70-100㎡/h |

Wire diameter | 1.6-4mm |

Mesh opening | 20-100mm |

Weaving width | Max. 3M |

Max length of mesh | 30m, adjustable freely as your request. |

Raw material | Galvanized wire, PVC Coated wire, etc. |

Motor | 4.5kw Delta servo motor + 2.2KW weaving plate turning +1.1KW cutting wire + 0.75KW*2 mesh ends + 0.75KW mesh hole holding + 0.75KW mesh tension + 1.1KW mesh rolling. |

Voltage | 220-240 v 50/60 hz |

Dimension | 4.2*2.2*1.7M (15CBM) |

Weight | 2.3T |

Flexible Width & Length Customization

Clients love the ability to freely adjust mesh lengths up to 30 meters and choose weaving widths from 1 to 6 meters—an industry-leading range. It means one machine can serve multiple contracts without retooling.

High-Speed Production

With a capacity of 70–100㎡ per hour, it's one of the fastest machines in its class, offering excellent return on investment for high-volume orders.

Robust Drive & Control System

Powered by a combination of Delta Servo motors, Teco electric systems, and Mitsubishi PLC, you get flawless synchronization, smooth mesh formation, and precise cutting/rolling.

Energy Efficient

The 9KW power system ensures efficiency, reducing long-term operational costs while maintaining stable performance.

User-Friendly PLC Control

Fully automated with touchscreen interface, the machine allows real-time adjustments, alarm systems, and low-maintenance operation—ideal for both novice and professional operators.

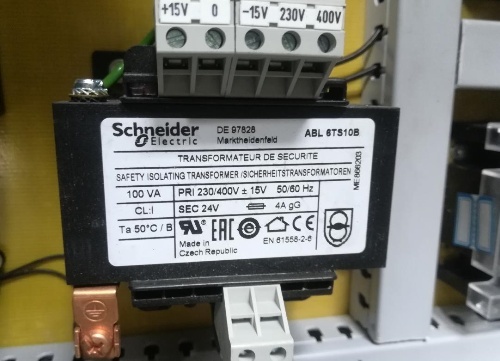

Core components

Core components——make Automatic Chain Link Fence Machine run stably and have a longer life, Machine electronic components equips good brand like Japan Mitsubishi, France Schneider very easy to operate, making the service life of machine longer

Advantages

Video

Edge Processing

Auxiliary Equipment

Applications

Chain link Fence is extensively used as fences for playground and gardens, highway, railway, airport, port, residence, etc.

Global Cases

Comparison

FAQ

1. How does the Economy Model help me reduce the initial setup cost for a new factory?

This model is designed with a simplified mechanical structure, reducing the initial investment by 30%–40% compared to fully automated high-speed lines. It offers the fastest Return on Investment (ROI) for small workshops by focusing on core functionality—stable weaving with lower overhead costs.

2. What are the hidden costs of running this machine, such as spare parts and electricity?

We’ve optimized this machine for low operational costs. It uses standard electrical components and a 7.5kW-11kW motor, which consumes significantly less power than industrial-grade lines. Most spare parts are standard mechanical items available locally, minimizing your long-term maintenance budget.

3. Do I need a highly skilled engineer to operate this machine daily?

Not at all. This entry-level model features a "One-Key Start" simplified control panel. Its manual adjustment points are intuitive and clearly marked. A single operator can manage 2-3 machines simultaneously after just one day of training, significantly reducing your reliance on expensive technical labor.

4. Can this compact machine still produce different mesh sizes and widths for various customers?

Yes. Despite its affordable price, it is highly versatile. It can produce mesh widths from 0.5m to 4.0m and hole sizes from 25mm to 100mm. Switching between mesh sizes only requires changing a simple weaving mandrel (screw), which takes about 45 minutes.

5. Is the machine durable enough to handle continuous production in hot or dusty environments?

Built for durability, the frame uses high-grade reinforced steel to prevent deformation during long-term use. We use heat-treated alloy steel for all key contact parts to resist wear. This ensures the machine remains stable and accurate even in the challenging environments often found in developing markets.

6. What happens if the machine encounters a mechanical jam or wire feeding error?

Safety and protection are built-in. The machine includes an Automatic Fault-Stop System. If the wire becomes tangled or the weaving process is interrupted, the machine stops instantly to prevent damage to the molds. This "fail-safe" design protects your investment from operator errors.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.