Leveling, Slitting and Cutting Machine

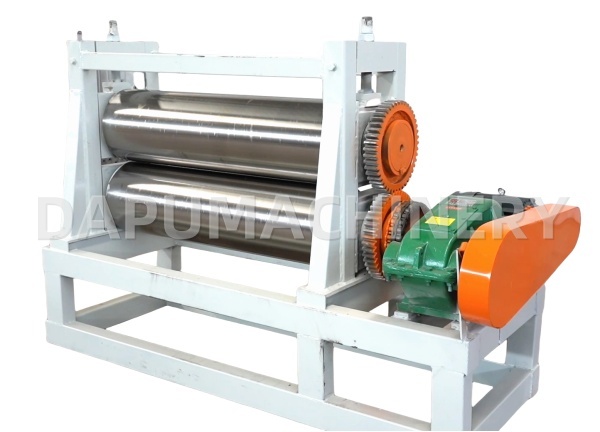

DP-30T Expanded Metal Mesh Machine

Built specifically for the high demands of emerging markets. The DP-30T offers the best cost-to-performance ratio, handling material up to 2.2mm thickness with superior energy efficiency. Its robust, low-maintenance design ensures maximum uptime and a fast Return on Investment (ROI). Featuring intuitive PLC controls, this machine delivers consistent, high-volume output while reducing reliance on skilled labor. Start producing high-quality mesh reliably and affordably today.

Key words:

Classification:

Product Description

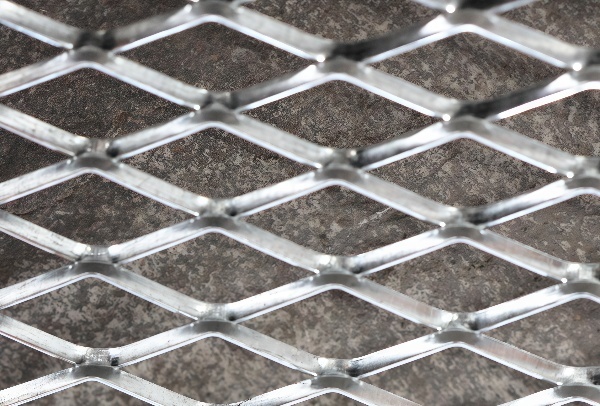

Expanded metal mesh machine can produce expanded metal mesh which is widely used in construction, hardware, window and door, machine protection etc. It can be produced width max.1200mm and thickness of metal sheet max.1.5mm. The material for expanded metal mesh can be low carbon steel plate, stainless steel plate, aluminum plate, copper plate and so on.

Technical Parameter

| Model | DP-30T |

| Material thickness | 0.2-1.2mm |

| Material max. width | 1600mm |

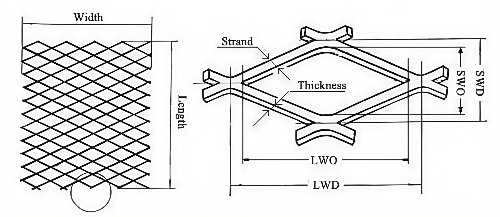

| LWD of mesh opening | 40mm |

| Distance of feed | 0-5mm |

| Speed (R/m) | 180 |

| Motor | 7.5/960 |

| Net weight | 4.1T |

Optional Equipment

Finished Product

It is widely used in construction, hardware, window and door, machine protection etc.

Order delivery

Other models

FAQ

How does the DP-30T achieve a balance between affordability and reliable performance?

DAPU focuses on optimizing core engineering. The DP-30T utilizes a highly efficient transmission system and high-quality, standardized components. This design keeps the initial purchasing cost low while maintaining the rigidity and punching accuracy needed for reliable, continuous operation, ensuring a fast ROI.

2. What is the typical operational speed (SPM) of the DP-30T, and how does it compare to the larger 63T model?

The DP-30T typically operates at a reliable speed of 120 to 200 strokes per minute (SPM), depending on the material thickness. While the 63T is faster when running its maximum capacity, the 30T offers superior cost-efficiency for thinner materials ($<1.5$ mm), making it very competitive for high-volume light mesh production.

3. What is the maximum material thickness and width the DP-30T can handle, making it suitable for general construction needs?

The DP-30T is expertly designed for the mass production of standard mesh. It can efficiently process materials up to 2.2 mm thickness (mild steel) and a maximum sheet width of 1250 mm. This capacity perfectly covers most common requirements for plastering, protective cages, and basic fencing in emerging markets.

4. Is the DP-30T suitable for beginners or small-scale manufacturers who are new to expanded metal production?

Yes, absolutely. The DP-30T is one of our recommended entry-level models. It features simplified controls, requires a smaller operational footprint, and its maintenance routine is very straightforward. We provide specialized training kits to help new manufacturers quickly master the production process.

5. What types of coils or sheet materials are recommended to feed the DP-30T efficiently?

We recommend using standard coil stock (up to 3-5 tons) with an associated Light-Duty Decoiler to ensure smooth and uninterrupted feeding at higher speeds. The machine handles galvanized steel, cold-rolled steel, and aluminum sheet particularly well.

6. How does the die replacement process work on the DP-30T, and can it produce different mesh sizes easily?

The DP-30T is designed for quick pattern changes. The die cassette system allows the entire die set to be exchanged with minimal complexity. By changing the die and adjusting the feed parameter on the PLC, you can easily switch between various LWD/SWD (Long Way of Mesh/Short Way of Mesh) dimensions in under two hours.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.