Leveling, Slitting and Cutting Machine

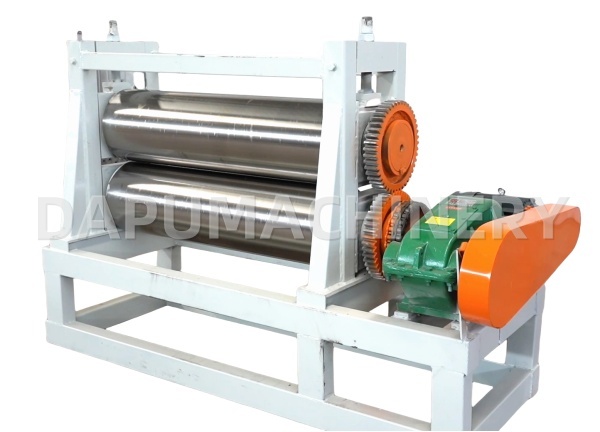

DP-100T Expanded Metal Mesh Machine

The optimal solution balancing power and speed. The 100T reliably processes materials up to 4.0mm thickness and a wide range of metal types, making it ideal for walkways, filtration, and standard industrial fencing. Built with a heavier, reinforced frame and advanced lubrication, it ensures superior stability and less vibration than lighter models. Minimize material waste and secure consistent, high-quality output for mid-to-heavy projects.

Key words:

Classification:

Product Description

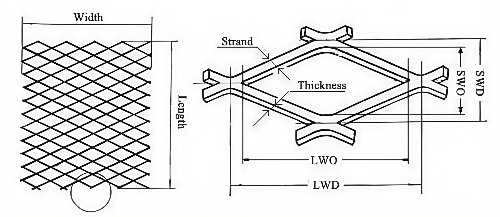

Expanded metal mesh machine can produce expanded metal mesh which is widely used in construction, hardware, window and door, machine protection etc. It can be produced width max.1200mm and thickness of metal sheet max.1.5mm. The material for expanded metal mesh can be low carbon steel plate, stainless steel plate, aluminum plate, copper plate and so on.

Technical Parameter

| Model | DP-100T | |

| Material thickness | 0.5-5mm | 0.5-5mm |

| Material max. width | 2000mm | 2500mm |

| LWD of mesh opening | 180mm | 180mm |

| Distance of feed | 0-10mm | 0-10mm |

| Speed (R/m) | 60 | 56 |

| Motor | 18.5/1470 | 22/1470 |

| Net weight | 13T | 14T |

Optional Equipment

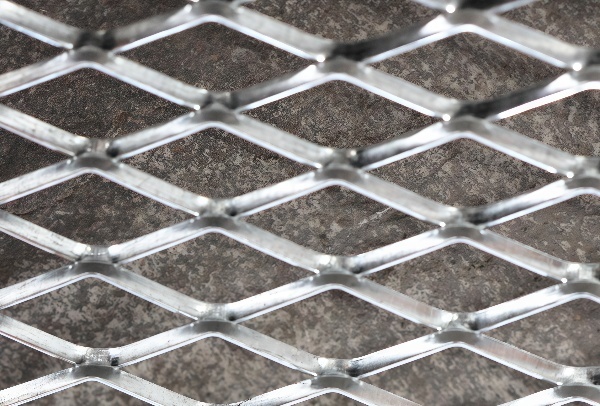

Finished Product

It is widely used in construction, hardware, window and door, machine protection etc.

Order delivery

Other models

FAQ

1. What is the maximum material thickness and width the DP-100T model can efficiently process?

The DP-100T is a versatile heavy-duty machine. It is optimally designed to process materials up to 4.0 mm thickness (mild steel) and a maximum sheet width of 1500 mm. This makes it an ideal choice for manufacturing heavy industrial platforms, walkways, and protective fences.

2. Compared to the 63T model, what is the key advantage of the 100T's enhanced mechanical structure?

The 100T utilizes a heavier, reinforced frame and a larger flywheel system. This design delivers significantly higher impact force and stability, reducing vibration when punching thicker material. This results in superior product flatness and a longer service life for the machine structure itself.

3. Which industries in developing countries commonly use the mesh produced by the DP-100T?

Mesh from the DP-100T is highly sought after in Construction (concrete reinforcement), Oil & Gas (stair treads, filtration supports), Mining (safety barriers), and Infrastructure projects. Its robust mesh quality meets international safety and load-bearing standards.

4. How does the DP-100T handle the stress and heat generated when running 3mm+ thick steel?

We equip the DP-100T with an enhanced forced lubrication and cooling system. This system continuously cycles oil to the critical moving parts and the die area, effectively dissipating heat and minimizing wear, which is crucial for maintaining performance during high-intensity, thick-material processing.

5. What are the common roll-forming equipment recommended to pair with the DP-100T for a complete production line?

For a seamless process, we recommend pairing the DP-100T with a Hydraulic Decoiler (for heavy coils), an Automatic Leveling Machine (to ensure flatness before punching), and a Heavy-Duty Flattening Machine to reduce the mesh profile post-expansion.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.