Gabion Mesh Machine

Engineered for the toughest environmental engineering projects, our Gabion Machine delivers high-speed production of double-twisted hexagonal mesh with unmatched stability. It supports heavy-gauge galvanized and PVC-coated wires up to 4.0mm, ensuring every roll meets ASTM and EN international standards. With an automated PLC system and reinforced twisting gears, DAPU provides a low-maintenance, high-output solution that turns raw wire into high-value civil engineering assets. Dominate the river-control and soil-erosion market with the industry's most trusted machine.

Key words:

Classification:

Product Description

|

| Twists selection: double twists (3 cross) or three twists (5 cross) or double twists share with three twists (3 cross share with 5 cross together) |

|

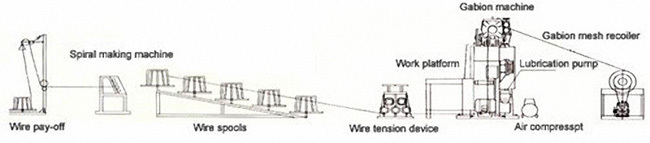

| There are always 4 steps in current production, which use 4 different machines. (Raw wire tension device, mesh roller, wire netting machine and wire spiral coil machine) |

| video: |

| Description: |

Gabion mesh machine is also known as heavy duty hexagonal wire mesh machine, which is professional equipment to produce hexagonal wire mesh. The “Dapu” heavy-duty hexagonal wire mesh machine, produced by this company is a special braiding machine to fabricate hexagonal mesh work, which is a new developed market-suitable product integrating the merits of domestic and oversea products. It is consisted of five series with fifteen models and the maximum width of mesh braiding is 4.2m. It is widely used in petroleum, construction, farming, chemical industry, heating pipes and other pipes parcel wire mesh; It also can be used for fencing, residential and landscape protection, etc. While it is also good material which is used to make stone wire mesh cages, which are widely used to protect and support the seawall, hillsides, road and bridge, reservoirs and other civil engineering, also it is the best material for flood.

Heavy duty hexagonal wire mesh machine adopts PLC automatic control, which have smooth operation, low noise and high efficiency characteristics. It is ideal machinery to product large specifications, wider breadth and thick wire diameter hexagonal wire mesh.

We also accept any special order from clients. Twists selection: double twists(3 cross); three twists(5 cross);

Double twists share with three twists (3 cross share with 5 cross together)

| Technical Parameter: |

| Model | DP-LNWL 4300 |

| Wire diameter | 1.6-3.5mm |

| Selvedge wire diameter | Max. 4.3mm |

| Grid size | 60*80 / 80*100 / 100*120 / 120*150 mm |

| Note | Each set machine only can make single grid size |

| Mesh width | Max. 4300 mm |

| Can make several rolls at same time | — |

| Motor | 22 kw |

| Production | 60*80mm-- 165 m/hour 80*100mm-- 195 m/hour 100*120mm-- 225 m/hour 120*150mm-- 255 m/hour |

| Also can be customized according to your specifications | |

| Auxiliary Equipments: |

|

Brief Introduction: Spiral Coiling Machine is assembled with heavy series twister for hexagon metal wires meshes. The machine is equipped by four pieces of wire-coiling bars, which can rotate in synchrony by to-and-fro way for layers of wire-spiral-coiling, to increase the length of wire spiral and to reduce the time of wire spiral changing during twisting to increase mesh-twisting efficiency. This machine, after changing the preset exchange gears, can meet the wire-spiral-coiling. functions for different diameter of wires |

|||||||||||||||

|

|

||||||||||||||

|

|

||||||||||||||

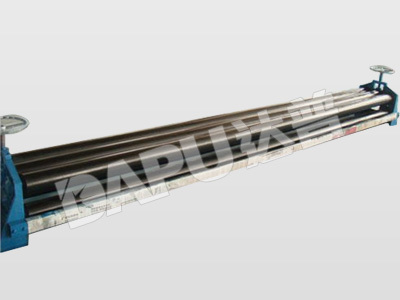

| Mesh roller | Wire tension device | ||||||||||||||

| Finished Products & Application: |

It is widely used in petroleum, construction, farming, chemical industry, heating pipes and other pipes parcel wire mesh; It also can be used for fencing, residential and landscape protection, etc. While it is also good material which is used to make stone wire mesh cages, which are widely used to protect and support the seawall, hillsides, road and bridge, reservoirs and other civil engineering, also it is the best material for flood.

|

|

| Gabion Box | Gabion Box |

| The Optional Equipment: |

|

Two different selvedging form 1) Edge Bending Machine 2) Portable Edge Bending Machine 3) Mesh shearing machine |

FAQ

1. Can the machine handle heavy-duty galvanized and PVC-coated wire without damaging the coating?

Yes. Our Gabion Mesh Machines are specifically designed with enlarged, polished guiding rollers and a soft-tension feeding system. This ensures that even heavily galvanized wire (up to 300g/m²) or PVC-coated wire is processed smoothly without any scratching or peeling of the protective layer. This is critical for ensuring the 50+ year lifespan of the finished gabion baskets in corrosive river environments.

2. What is the maximum wire diameter and mesh size range this machine can produce?

Our heavy-duty series can handle wire diameters from 2.0mm up to 4.0mm (selvage wire can be even thicker). Regarding mesh sizes, we offer standard configurations such as 60x80mm, 80x100mm, 100x120mm, and 120x150mm. The machine’s modular design allows for some flexibility, enabling you to meet various international engineering specifications with a single production line.

3. How does the machine ensure the "Double-Twisted" structure meets international safety standards?

To comply with standards like ASTM A975 or EN 10223-3, our machine utilizes a high-torque, synchronized twisting mechanism. This ensures that the three full twists (double-twist) are tight, uniform, and resist unraveling even under extreme structural stress. The integrated PLC control system monitors the twisting cycle in real-time, guaranteeing consistent mechanical properties across every square meter of mesh.

4. What is the production efficiency, and how many workers are required to operate the line?

Efficiency is a core advantage of DAPU machines. Our standard models can achieve a theoretical speed of 225-275 meters per hour. Because the line is fully automated—including wire feeding, weaving, and mesh rolling—a single skilled operator can manage the entire production process. This significantly lowers labor costs and increases your competitive edge in large-scale government tenders.

5. What maintenance is required for the twisting gears in high-intensity production?

The twisting gears are the heart of the machine. We use heat-treated alloy steel for all key components to ensure maximum wear resistance. For maintenance, we have integrated a centralized automatic lubrication system that delivers oil to critical friction points at set intervals. This minimizes manual intervention and prevents unexpected downtime, ensuring the machine remains a reliable asset for 24/7 industrial production.

6. What is the expected Return on Investment (ROI) for a DAPU Gabion Machine in today's market?

Based on our global client data, the ROI typically occurs within 8 to 14 months of continuous production. The high-speed output (up to 300m/h) combined with a low scrap rate (less than 1%) significantly reduces the cost per square meter. As infrastructure projects increasingly specify double-twisted mesh for soil retention, the market demand for Gabions continues to outpace manual production methods, ensuring a steady stream of high-margin orders.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.