Automatic oil lubrication system, can lubricate whole machine automatically

DAPU Expanded Metal Mesh Machine

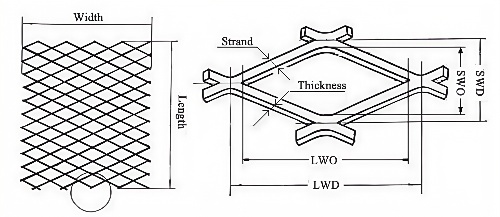

DAPU Expanded Metal Mesh Machine punching dies allow quick hole size changes by replacing the upper cutter. The alloy mold is suitable for aluminum, iron, and galvanized steel sheets, while the white mold handles stainless steel. Designed for durability and efficiency, DAPU ensures stable performance across various materials. Our expanded metal production line can produce a variety of expanded metal machines, from light to heavy. Please refer to the parameter table below.

Key words:

Product Description

Our advantages

DAPU Resolves What Matters Most to You

Multi-Material Compatibility

Our machines are engineered to handle carbon steel, stainless steel, aluminum, and galvanized sheets with ease — ensuring consistent performance regardless of material type.

Flexible Mesh Specifications

Quick and precise adjustment of mesh hole size and shape lets you produce a wide range of patterns for different applications — from fine filtration to heavy-duty panels.

High Degree of Automation

Whether you need fully automatic or semi-automatic solutions, we offer customizable levels of automation to match your budget and production demands.

Optimized Output-to-Energy Ratio

We focus on high production efficiency with minimal energy consumption, ensuring you get more output at lower operational costs.

Versatile Application Support

From construction and fencing to filters and decorative panels, our machines are built to meet the diverse needs of your industry with precision and reliability.

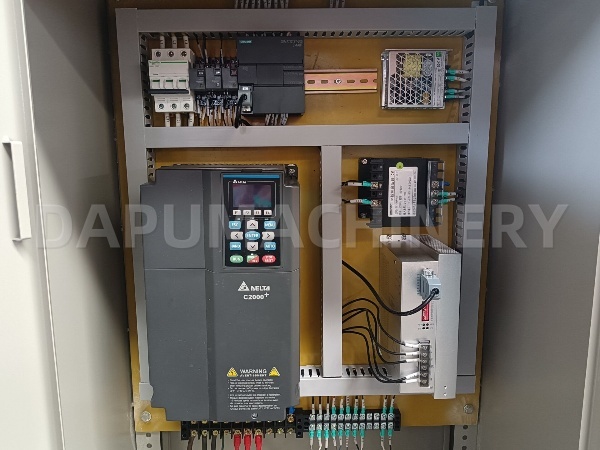

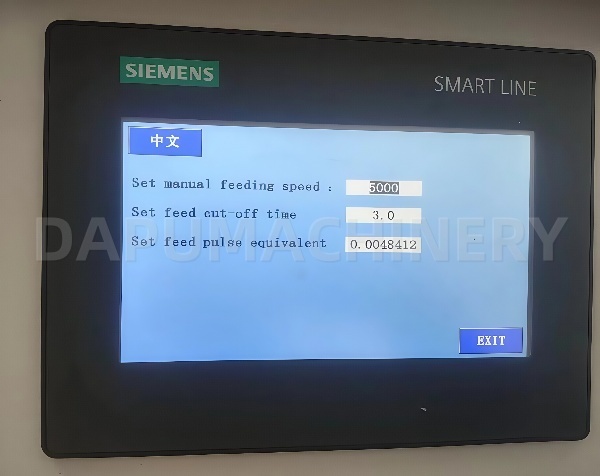

DAPU CNC-controlled expanded metal mesh machine, the whole machine uses European design technology and is composed of a main frame, drive system, feeding device, material moving device, lubrication system, and electrical control parts. It is widely used in construction, hardware, doors and windows, mechanical protection,n, and other industries. DAPU Expanded metal mesh machine has 18 specifications and models to meet the needs of different industries. You can click on the major categories on the left to view them. The material of the expanded metal mesh can be a low-carbon steel plate, stainless steel plate, aluminum plate, copper plate, etc.

1. The machine is equipped with a servo drive

2. PLC control

3. High-speed production

4. The finished product can be rolled into a mesh or cut into a single mesh, which is convenient for transportation or further processing.

5. Each machine is equipped with a unique "Knife" dedicated to a specific pattern

Technical Parameter

| Model | Punch Speed R/m | LWD Max. | Thick. | Width Max. | Feeding Distance | Motor | Weight(t) | L*W*H |

| 6.3T | 300 | 20 | 0.2-1.5 | 650 | 0-5 | 4/1440 | 1.2 | 800*1400*1520 |

| 16T | 260 | 30 | 0.2-1.5 | 1000 | 0-5 | 5.5/1440 | 2.8 | 1350*1880*1930 |

| 25T/1.2 | 260 | 30 | 0.2-1.5 | 1250 | 0-5 | 5.5/1440 | 3.3 | 1350*2250*1930 |

| 25T/1.5 | 260 | 30 | 0.2-1.2 | 1500 | 0-5 | 5.5/1440 | 3.9 | 1350*2500*1930 |

| 30T/1.6 | 180 | 40 | 0.2-1.2 | 1600 | 0-5 | 7.5/960 | 4.1 | 1350*2600*2000 |

| 63T | 75 | 120 | 0.5-3 | 2000 | 0-5 | 15/1440 | 11 | 2000*3950*2300 |

| 100T | 60 | 180 | 0.5-5 | 2000 | 0-10 | 18.5/1470 | 13 | 3300*3700*2500 |

| 56 | 180 | 0.5-5 | 2500 | 0-10 | 22/1470 | 14 | 3300*4200*2500 | |

| 160T | 55 | 200 | 0.5-6 | 2000 | 00-10 | 30/1470 | 16 | 3550*3800*2650 |

| 45 | 200 | 0.5-5 | 2500 | 00-10 | 30/1470 | 20 | 3550*4300*2650 | |

| 260T | 32 | 200 | 1-8 | 2000 | 00-10 | 55/1470 | 26 | 3700*4400*2700 |

| 32 | 200 | 1-8 | 2500 | 0-10 | 55/1470 | 28 | 3700*4900*2700 | |

| TG10 | 500 | 12 | 0.1-1.0 | 650 | 0-6 | 7.5/1000 | 1.5 | 1750*740*1250 |

| G35 | 400 | 20 | 0.05-1.5 | 1250 | 0-10 | 11/1000 | 7 | 2350*1000*2080 |

| 400 | 20 | 0.05-1.5 | 1250 | 0-10 | 11/1000 | 7 | 2350*1000*2080 | |

| TG10 | 500 | 12 | 0.1-1.0 | 650 | 0-6 | 7.5/1000 | 1.5 | 1750*740*1250 |

Optional Equipment

Finished Product

It is widely used in construction, hardware, window and door, machine protection etc.

Order delivery

Other models

FAQ

1. What is the primary factor I should consider when choosing between a high-tonnage (100T+) and a low-tonnage (25T) Expanded Metal Machine?

The core factor is your maximum required material thickness and strength. High-tonnage machines (like the 100T or 160T) are necessary for processing heavy-gauge steel (up to 6mm) for construction or oil industries. Low-tonnage machines excel at high-speed production of thin materials (e.g., aluminum, decorative mesh up to 2.0mm) where precision and speed are key.

2. How does DAPU ensure the expanded mesh product has a uniform hole size and clean edges, even at high speed?

DAPU machines feature a precision-guided ram system and low-friction rolling mechanism. Most importantly, we use Cr12MoV premium tool steel dies that are heat-treated and precision ground, minimizing wear and ensuring a consistent cut (LWD and SWD) and a clean strip throughout the entire coil.

3. What is the typical lifespan of the main cutting dies, and what are the replacement costs like for DAPU machines?

The lifespan is generally determined by the material and thickness processed. For medium-carbon steel, our dies typically last between 8 to 12 months (or 100.000+ punching cycles) before requiring regrinding or replacement. DAPU offers dies directly from our factory at a highly competitive price with quick global shipping, significantly reducing your long-term operational costs.

4. Is it possible to switch production quickly between different mesh patterns (e.g., from diamond mesh to hexagonal mesh) on one machine?

Yes, our machines are designed for high flexibility. Changing the mesh pattern primarily involves replacing the cutting die set and adjusting the feed mechanism. On our latest DP-series, this tooling changeover can be completed by trained personnel in under 2 hours, maximizing your uptime and product versatility.

5. Can DAPU machines handle specialized materials like stainless steel, galvanized steel, or aluminum?

Absolutely. DAPU machines are built with high-strength components and flexible lubrication systems. We often recommend specific anti-wear coatings on the dies and higher-tonnage models for processing Stainless Steel (304/316) to ensure machine longevity and consistent quality.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.