Nail Making Machine

Our nail making machine is designed for high-speed and stable production, making up to 800 nails per minute with low waste and high precision. It supports wire sizes from 1.8mm to 5.5mm, allowing you to produce different types of nails with one machine. The easy-to-use control panel means even one worker can run the machine without technical training. Built with durable parts, it runs 24/7 with minimal maintenance and helps reduce downtime. This machine is perfect for small factories or new businesses looking for fast return on investment.

Key words:

Classification:

Product Description

|

|

| High Speed Model | Normal Model |

| Description: |

This new type machine adopts plunger and oil pipe lubricating structure to ensure the high working speed, low noise and less impact. Especially, it can make the high quality coil nails used in the nail gun. It has the features of advanced design, compact conformation, and attractive appearance. It is easy and safe to operate.

| Technical Parameter: |

| Modelo | DP-ZDJ-L50 | DP-ZDJ-L90 | DP-ZDJ-L100 | DP-ZDJ-L130P | DP-ZDJ-L150 |

| Wire diameter | 1.8-2.5mm | 2-3.5mm | 2-3.8mm | SS steel: 2.5-4.8mm Low carbon: 2.5-5.2mm |

SS steel: 2.5-4.8mm Low carbon: 2.5-5.5mm |

| Nail Length | 32-64mm | 32-92mm | 40-100mm | 50-130mm | 70-150mm |

| Speed | 800pcs/min | 760pcs/min | 860pcs/min | 650pcs/min | 500pcs/min |

| Motor | 5.5kw + 1.5kw | 5.5kw + 1.5kw | 5.5kw + 1.5kw | 7.5kw + 2.2kw | 11kw + 2.2kw |

| Dimension | 1500*950*1300mm | 1500*1180*1100mm | 1560*1200*1380mm | 1540*1160*1300mm | 1650*1200*1300mm |

| Weight | 2500kg | 2800kg | 2600kg | 4200kg | 4500kg |

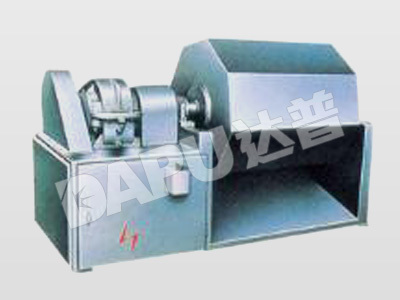

| Auxiliary Equipment: |

|

|

|

| Wire wheel | Nail cutter grinder | Nail washing machine |

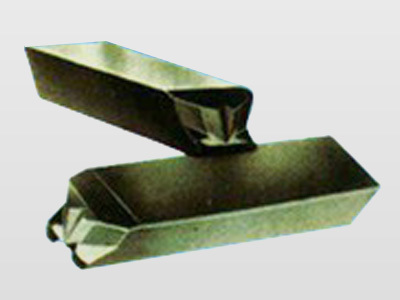

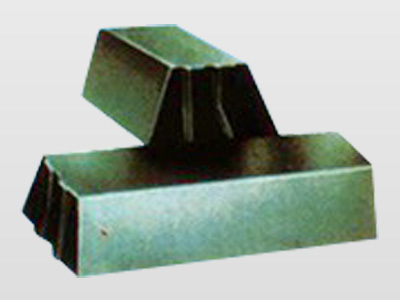

| Spare parts: |

|

|

|

| Punch pin | Nail knife | Nail mould |

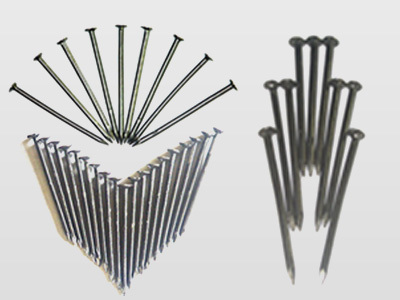

| Finished Product & Application: |

|

|

|

| Video: |

FAQ

1. What range of nail sizes can a single machine produce?

Our machines are highly adjustable. A standard model can typically produce nails from 25mm to 100mm (1" to 4") in length. By simply changing the nail molds (gripping dies) and adjusting the feeding stroke, you can switch between different lengths and wire diameters (gauges) to meet various construction demands.

2. How does the machine ensure the nail head is perfectly centered and uniform?

Precision is achieved through our centralized punching mechanism. The machine uses a high-carbon steel punch that strikes the wire end while it is firmly clamped by the gripping dies. This synchronized action ensures that every nail head is circular, centered, and of consistent thickness, meeting international hardware standards.

3. Can this machine produce specialized nails like Concrete or Roofing nails?

Yes. By equipping the machine with reinforced alloy punches and specific dies, you can produce Concrete nails (using high-carbon wire). For Roofing nails, we offer an integrated large-head attachment. The flexibility of the DAPU design allows you to diversify your product line with minimal additional investment.

4. What is the expected lifespan of the core wear parts (Dies, Cutters, Punches)?

We use premium Tungsten Carbide or D2 alloy steel for all cutting and punching tools. Under normal conditions and with proper lubrication, a set of nail cutters can last for several hundred tons of production before needing regrinding. We also provide a "Quick-Replace" kit to ensure your production line stays active 24/7.

5. How does the machine handle the waste (wire scraps) generated during the process?

Our machines feature an automatic scrap separation system. As the nail is cut and the point is formed, the tiny wire fragments (nibs) are automatically funneled into a separate collection bin. This keeps the finished nails clean and prevents scrap buildup from interfering with the high-speed mechanical parts.

6. Is it difficult for a new operator to learn how to calibrate the machine?

Not at all. The DAPU Nail Making Machine is famous for its "Low-Maintenance" mechanical design. We provide comprehensive video tutorials and a detailed calibration manual. Most operators can learn to adjust the nail length, wire feeding, and cutting depth within a single afternoon of training.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.