Leveling, Slitting and Cutting Machine

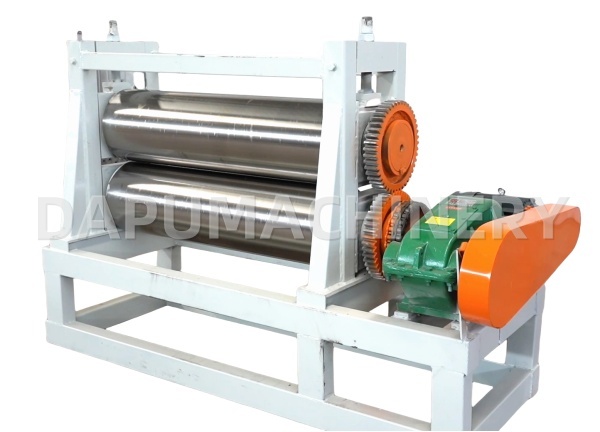

DP-63T Expanded Metal Mesh Machine

The DP-63T is DAPU’s most popular model, offering the perfect blend of affordability, speed, and capability. Reliably process materials up to 3.0mm thickness with speeds up to 180 SPM. Ideal for plaster mesh, security fencing, and general construction applications. Its robust, simple-to-maintain structure ensures maximum uptime and efficiency, making it the fastest path to a profitable Return on Investment (ROI) for general manufacturing needs.

Key words:

Classification:

Product Description

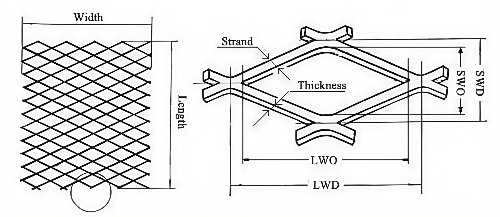

Expanded metal mesh machine can produce expanded metal mesh which is widely used in construction, hardware, window and door, machine protection etc. It can be produced width max.1200mm and thickness of metal sheet max.1.5mm. The material for expanded metal mesh can be low carbon steel plate, stainless steel plate, aluminum plate, copper plate and so on.

Technical Parameter

| Model | DP-63T |

| Material thickness | 0.5-3mm |

| Material max. width | 2000mm |

| LWD of mesh opening | 120mm |

| Distance of feed | 0-5mm |

| Speed (R/m) | 75 |

| Motor | 15/1440 |

| Net weight | 11T |

Optional Equipment

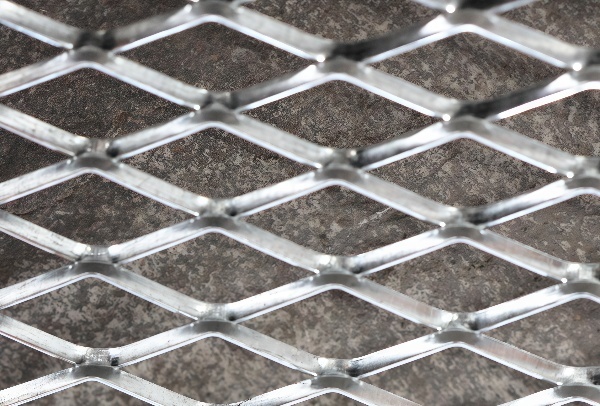

Finished Product

It is widely used in construction, hardware, window and door, machine protection etc.

Order delivery

Other models

FAQ

1. Why is the DP-63T considered the most popular 'workhorse' model for new mesh manufacturers?

The DP-63T offers the best balance of price, versatility, and performance. It can handle most common materials (up to 3.0 mm mild steel) at a respectable speed (up to 180 SPM), making it highly profitable for general-purpose applications like plastering, security mesh, and walkways.

2. What is the typical output (in kg or m²/hour) of the DP-63T when running 2.0 mm galvanized sheet?

While output varies greatly, for a standard 2.0 mm mesh with a 25mm LWD, you can expect an average output of 150 to 200 m² per hour. This high-efficiency rate ensures rapid return on investment (ROI).

3. How does the 63T ensure low energy consumption while maintaining a solid punching force?

The DP-63T is optimized with an energy-efficient motor and a balanced flywheel mass. The flywheel's inertia ensures that the peak energy required for the punching stroke is minimized, leading to a substantial reduction in your overall electricity bill compared to older, unoptimized designs.

4. What are the common roll-formed mesh profiles (mesh aperture) that the DP-63T can produce?

The 63T is extremely versatile. It commonly produces diamond mesh for fencing, square mesh for filters, and can also be equipped with tooling for various hexagonal and special decorative patterns, allowing you to serve diverse market demands.

5. How does the maintenance of the DP-63T compare to the heavier 100T model?

Maintenance is simpler and less costly. The DP-63T has fewer ultra-heavy components, meaning routine upkeep (bearing checks, oil changes) is faster and requires less specialized lifting equipment. Its reliable design ensures minimal unexpected breakdowns.

6. Does DAPU offer a coil-to-mesh-to-flat finished product solution based on the 63T?

Yes, we design the full line. We can integrate the DP-63T with an Automatic Decoiler, an Online Flattening Machine, and a Shearing Machine to deliver a complete, automated solution that takes a coil of steel and outputs a ready-to-use, flat mesh sheet.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.