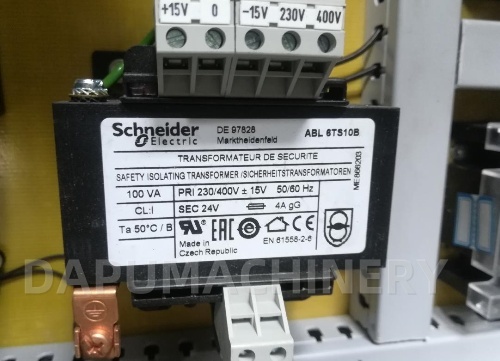

The electic relay can bear up to 660V tolerance, specially designed for the problem of unsteady voltage in some areas, avoiding burnt out.

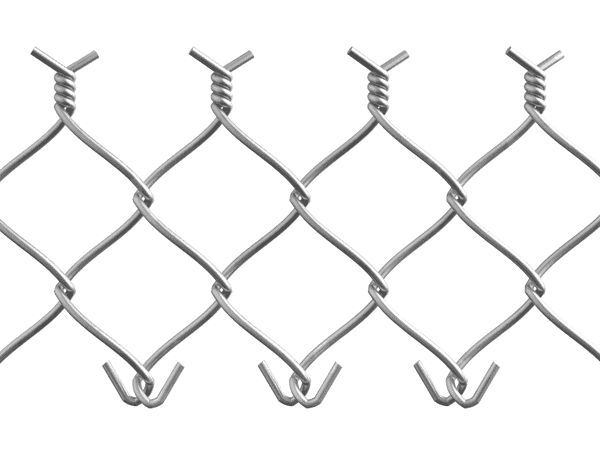

High Speed Chain Link Fence Machine

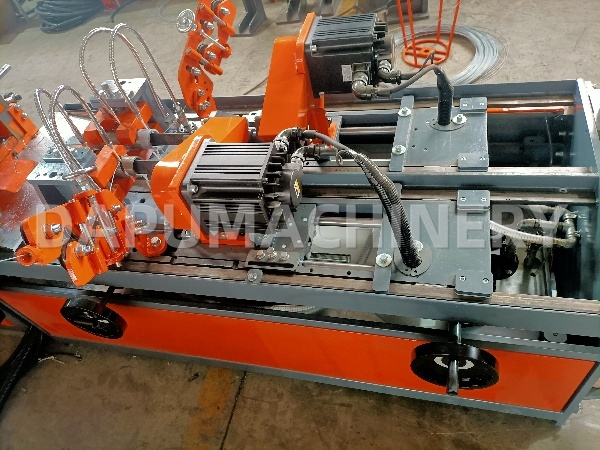

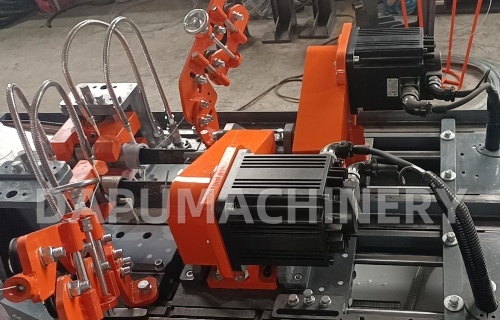

Automatic chain link fence machine DP20-100P is specially designed for mid- to high-end market needs, the raw material tensile strength can be 350- 800MPA. The capacity is 2 times higher as a traditional single wire chain link fence machine, which has been widely used in the world.

Key words:

Classification:

Product Description

Technical Parameters

Semi-automatic chain link fence machine is easy for operation and control.the surface of the chain link fence is flat after being arranged. this machine is automatic wire snipping and manual lock seaming to produce glattening mesh panel with credible performance of complete machine. The motor is electromagnetic inverter. This machine islittle failure and easy maintenance which is suitable for small enterprises.

Model | DP20-100P, Double motor single wire | |

Capacity | 40mm | 80-100 M²/h |

| 50mm | 120-160 M²/h |

| 60mm | 150-180 M²/h |

| 75mm | 180-200 M²/h |

| 100mm | 200-260 M²/h |

Wire diameter | 1.6-4mm | |

Mesh opening | 25-100mm | |

Weaving width | Max. 3M | |

Max length of mesh | 30m, adjustable freely as your request. | |

Raw material | Galvanized wire, PVC Coated wire, etc. | |

Motor | 2*4.5kw Delta servo motor + 1.5KW weaving plate turning +2.2KW cutting wire + 0.75KW*2 mesh ends + 0.75KW mesh hole holding + 0.75KW mesh tension + 1.1KW mesh rolling. | |

Voltage | Customized as your request. | |

Dimension | 7*6M | |

Weight | 4.2T | |

Core components

Core components——make the High Speed Chain Link Fence Machine run stably and have a longer life, Machine electronic components equips good brand like Japan Mitsubishi, France Schneider very easy to operate, making the service life of machine longer

Advantages

Video

Edge Processing

Auxiliary Equipment

Applications

Chain link Fence is extensively used as fences for playground and gardens, highway, railway, airport, port, residence, etc.

Global Cases

Comparison

FAQ

1. How does the Double-Wire feeding system work to achieve such high production speeds?

Unlike standard machines, our High-Speed model feeds two wires into the weaving mold simultaneously. This synchronized process allows the machine to weave two mesh lines at once, effectively delivering an output of up to 120-150 m²/hour (depending on mesh size). This makes it the most efficient solution for fulfilling high-tonnage orders in record time.

2. Can this high-speed model handle high-tensile wire and thick PVC-coated wire without jamming?

Yes. The machine is equipped with a heavy-duty servo-drive system and reinforced weaving molds made of high-chromium alloy. The feeding rollers are specially polished to ensure that PVC coatings are never scratched, and the high-torque motor handles high-tensile wire with ease, maintaining a smooth flow even at maximum RPMs.

3. What edge-finishing options are available (Knuckled vs. Twisted)?

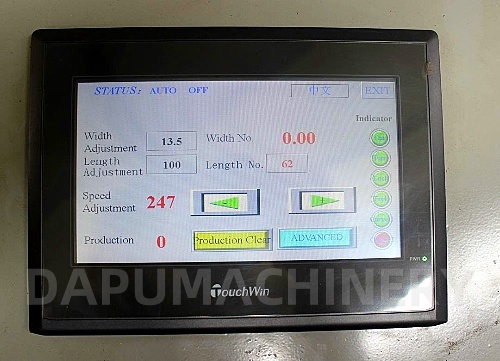

Our machine features a fully automatic universal edge-treatment unit. You can switch between Knuckled-Knuckled, Twisted-Twisted, or Knuckled-Twisted edges directly via the PLC settings. This flexibility allows you to supply both standard garden fencing and high-security industrial fencing with the same machine.

4. How does the machine prevent defects during high-speed operation if a wire tangles?

Safety is integrated into every cycle. The machine is equipped with ultra-sensitive infrared and mechanical sensors. If the wire knots, tangles, or breaks, the system triggers an instant emergency stop within 0.5 seconds. This prevents damage to the weaving mold and ensures that not a single meter of defective mesh is produced.

5. Is it difficult to change the mesh size (e.g., from 50mm to 75mm) on a CNC machine?

Not at all. DAPU’s Quick-Change Tooling System allows you to replace the weaving mandrel (screw) in about 30 to 45 minutes. Once the mold is swapped, you simply input the new parameters into the multilingual PLC touch screen, and the machine automatically recalibrates for the new mesh dimensions.

6. What is the expected ROI (Return on Investment) for this high-speed line?

Due to its high output and low labor requirement (one operator can manage two high-speed lines), most of our clients in emerging markets report a full ROI within 6 to 10 months. The ability to produce more mesh per kilowatt-hour also makes it the most energy-efficient choice for long-term industrial manufacturing.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.