How Automatic Crimped Wire Mesh Machines Enhance Mining and Construction Projects

Category:News

Author:

Source:

Add time:2025-05-14 11:00

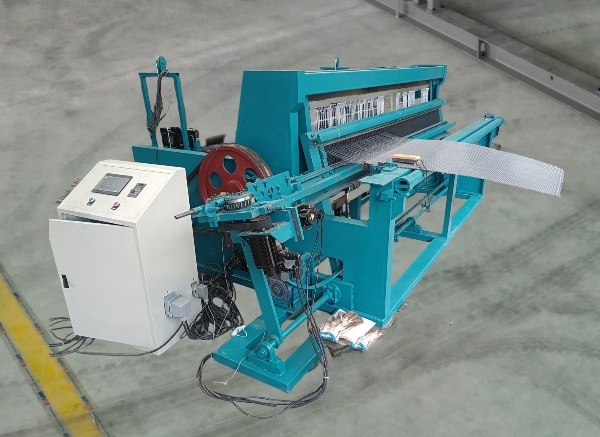

Mining and construction are pillars of economic growth in regions like South America, the Middle East, Southeast Asia, and Africa. From extracting minerals in Chile’s Atacama Desert to building skyscrapers in Dubai, these industries demand robust, efficient tools to tackle harsh environments and tight deadlines. One such tool revolutionizing these sectors is the automatic crimped wire mesh machine. Designed to produce durable, precision-engineered mesh screens, these machines are critical for tasks like mineral separation, soil stabilization, and structural reinforcement.

However, businesses in emerging markets often face challenges such as limited technical expertise, unreliable infrastructure, and budget constraints. This article explores how modern automatic crimped wire mesh machines address these pain points while boosting productivity in mining and construction—with a focus on DAPU’s Automatic Crimped Wire Mesh Machine, a game-changer for 2025.

Challenges in Mining and Construction

Before diving into solutions, let’s examine the hurdles faced by industries in these regions:

Harsh Operating Conditions: Dust, humidity, and heavy loads degrade equipment quickly.

Labor Shortages: Skilled operators are scarce, increasing reliance on automation.

Power Instability: Voltage fluctuations disrupt production in remote mining sites.

High Maintenance Costs: Frequent breakdowns inflate operational expenses.

Diverse Application Needs: Projects require mesh screens of varying sizes and strengths.

How Automatic Crimped Wire Mesh Machines Solve These Problems

Modern machines like the DAPU Automatic Crimped Wire Mesh Machine are engineered to overcome these challenges. Here’s how they enhance efficiency and durability in mining and construction:

1. Automation Reduces Labor Dependency

In regions with limited technical workforce, automation is a lifesaver.

PLC Control System: The DAPU machine uses programmable logic controllers (PLCs) to automate weaving, threading, and tension adjustments. Operators only need to input basic parameters, reducing human error.

Self-Correcting Mechanisms: Sensors detect wire misalignment or jams, pausing production until issues are resolved.

Impact: Mines in Peru or construction sites in Nigeria can maintain productivity even with minimal trained staff.

2. Built to Withstand Extreme Environments

Durability is non-negotiable for equipment used in quarries or desert construction zones.

Reinforced Steel Frame: Resists corrosion and mechanical stress.

Dust-Proof Components: Critical for mining operations in arid regions like Saudi Arabia.

Low-Maintenance Design: Lubrication-free bearings and easily replaceable parts minimize downtime.

Impact: Longer machine lifespan reduces replacement costs—a key advantage for budget-conscious projects.

3. Adaptable to Unstable Power Grids

Many remote sites lack reliable electricity.

Energy-Efficient Motor: The DAPU machine’s 1.5 kW servo motor consumes 30% less power than conventional models.

Custom Voltage Options: Standard 380V 3-phase but customizable for single-phase or low-voltage grids in rural Africa or Southeast Asia.

Impact: Consistent performance even during power fluctuations, ensuring uninterrupted production.

4. Precision for Critical Applications

In mining and construction, subpar mesh quality can lead to safety risks or project delays.

Tight Error Margins: Wire alignment accuracy within 1 mm ensures uniform mesh openings (5–50 mm).

Adjustable Speed (20–30 r/min): Operators can balance speed and precision based on material type (e.g., coal vs. iron ore).

Impact: High-quality screens improve mineral recovery rates in Chilean copper mines or stabilize soil in Vietnamese road projects.

5. Versatility Across Projects

One machine, multiple applications:

Mining: Produces screens for filtering slurry, sorting minerals, or reinforcing tunnels.

Construction: Weaves mesh for concrete reinforcement, slope stabilization, or fencing.

Adaptable Wire & Mesh Sizes: Handles wire diameters of 2–5 mm and mesh widths up to 2 meters.

Impact: Reduces the need to invest in multiple machines, saving capital for businesses in growing markets.

DAPU Machine: A Case Study in Efficiency

Let’s break down why the DAPU model stands out for mining and construction:

Key Specifications:

Motor: 1.5 kW (energy-efficient, low operational costs).

Speed: 20–30 rotations/minute (adjustable for precision tasks).

Weight: 2,500 kg (portable for on-site mobility).

Voltage: 380V 3-phase (customizable for regional needs).

Real-World Applications:

Coal Screening in South Africa: A mining company reduced downtime by 40% after switching to DAPU’s automated system.

Highway Construction in Indonesia: Contractors used DAPU mesh for erosion control, cutting material costs by 25%.

Why Choose Automation in 2025?

The global push toward industrialization in emerging economies makes automated machinery a smart investment. For mining and construction firms, benefits include:

Faster ROI: Automated machines like DAPU’s produce 500+ sq.meters of mesh daily, accelerating project timelines.

Safety Improvements: Reduced manual handling lowers injury risks in high-risk environments.

Scalability: Easily upgradeable software and modular designs future-proof your investment.

Conclusion

Automatic crimped wire mesh machines are no longer a luxury—they’re a necessity for mining and construction projects in fast-growing markets. The DAPU Automatic Crimped Wire Mesh Machine exemplifies this shift, offering durability, adaptability, and automation tailored to regions like South America, the Middle East, Southeast Asia, and Africa.

Whether separating gold ore in Ghana, reinforcing a dam in Brazil, or building infrastructure in India, this machine delivers precision and reliability where it matters most. As industries modernize, embracing such technology will be key to staying competitive in 2025 and beyond.

Upgrade your operations today with a machine designed for the challenges of tomorrow.

Recommend News