Mechanical sheller

Cold Rolling Ribbed Rebar Making Machine

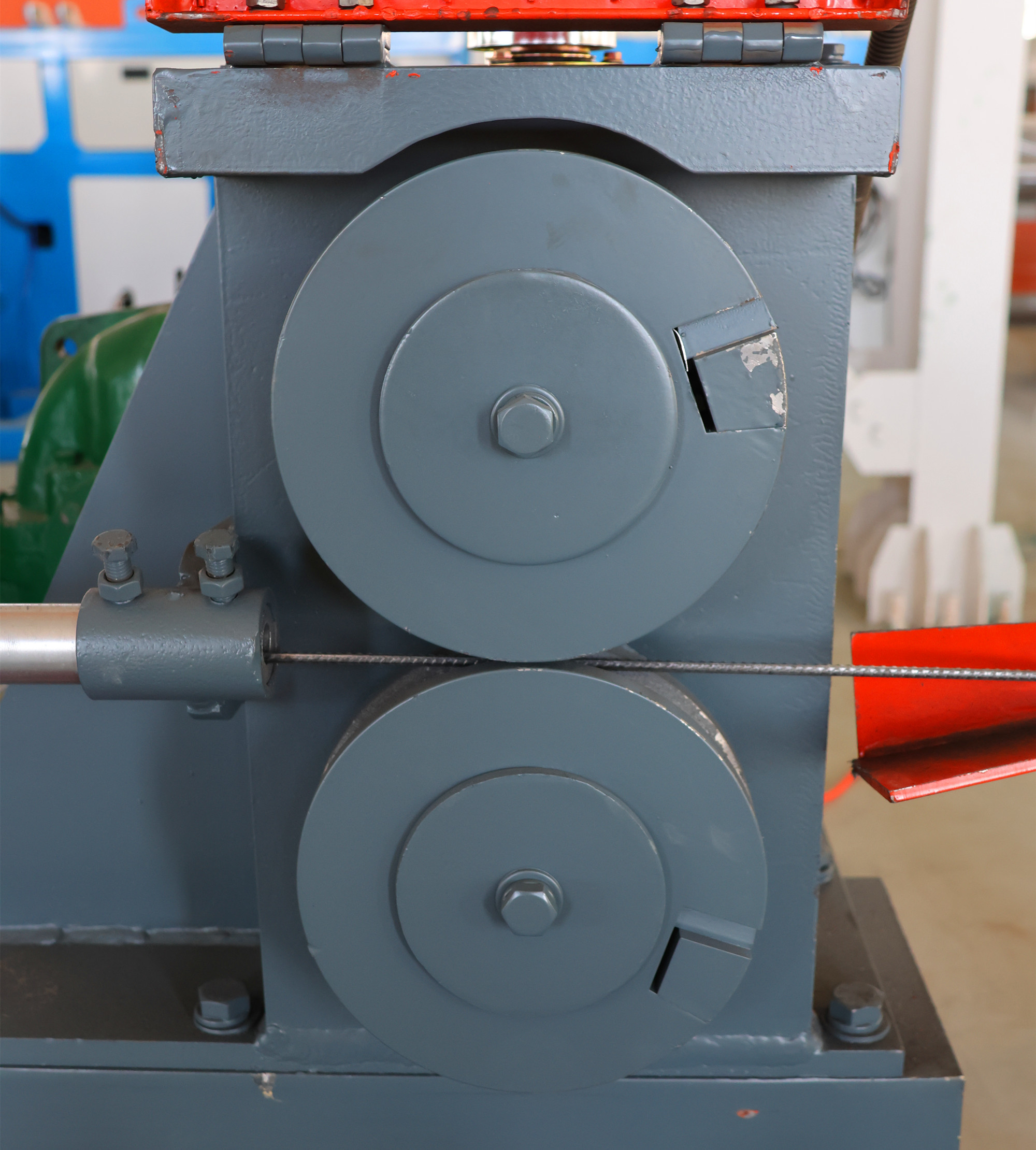

The Cold Rolled Steel Bar Making Machine is designed for continuous production of high-strength ribbed steel bars from low carbon steel wire rods. It combines precision cold rolling and ribbing processes to improve tensile strength and surface adhesion. Featuring automatic feeding, high-speed rolling, and PLC control, the machine ensures stable output, uniform rib patterns, and minimal deformation. With durable rollers and efficient cooling, it delivers long service life and reduced maintenance needs.

Key words:

Classification:

Product Description

Description

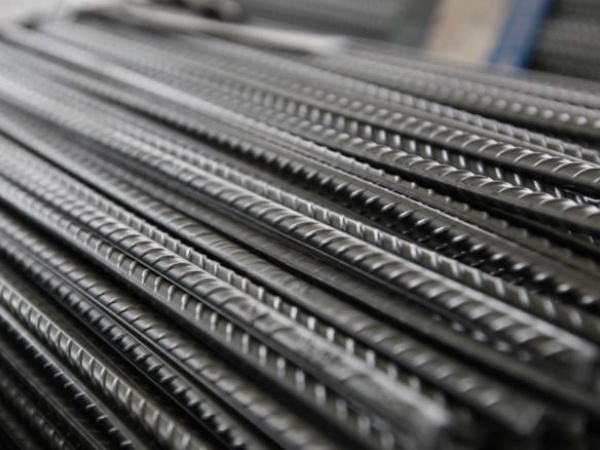

This production line mainly rolls diameter of 3.5—13mm and ordinary low carbon tray bar or low alloy tray bar with multiple cold rolling and a ribbing rolling, which finally forms reinforcing steel with three-side crescent shape ribs. It's widely applicable to highway, airport, irrigation works, city planning and construction engineering.

Technical Parameter

| Model | LZ-20000T |

| Raw material | 5.5–13 mm plain wire |

| Rebar diameter | 5–12 mm ribbed wire |

| Reduce diameter | Suggest less than 2 mm, more than 0.5 mm. 6 mm rebar: use 6.5–8 mm wire |

| Standard rib height | 6 mm rebar: 0.4 mm 8 mm rebar: 0.55 mm 10 mm rebar: 0.75 mm 12 mm rebar: 0.95 mm |

| Cutting length | Max. 12 m (CNC adjustable) |

| Motor capacity | 90 kW (drawing) + 30 kW (straightening) + 14 kW (cutting) |

| Straightening accuracy | ±2 mm |

| Cutting accuracy | ±5 mm |

| Working speed | Max. 120–150 m/min |

| Production capacity | 6 mm: 1600–2000 KG/hour 8 mm: 2840–3550 KG/hour 10 mm: 4440–5550 KG/hour 12 mm: 6400–8000 KG/hour |

| Weight | 6800 KG |

Video

Features / Benefits

High-Efficiency Ribbed Rebar Production

The Cold Rolled Steel Bar Making Machine is engineered for fast and efficient transformation of plain round wire into ribbed steel bars. With optimized drawing and rolling processes, it enables continuous production of 5–12mm ribbed rebar from 5.5–13mm raw material, making it ideal for high-demand construction applications.

Precision You Can Trust

This machine ensures consistently accurate straightening and cutting, with minimal tolerance errors. Rib height and bar dimensions meet standard construction requirements, helping manufacturers deliver high-quality products that comply with industry norms while reducing scrap and rework.

Smart and Flexible Operation

Equipped with CNC-controlled cutting and automated parameter adjustment, the machine allows quick changeovers between different bar sizes and lengths. Whether you’re producing 6mm or 12mm rebar, the intuitive interface and automation reduce manual involvement, improve efficiency, and shorten training time for operators.

Built for High Output

With a production speed of up to 150 meters per minute and the ability to handle different wire input sizes, this machine delivers impressive hourly output across multiple rebar specifications. It’s a perfect solution for producers aiming to scale up without compromising on quality or accuracy.

Electric Parts

Core electrical components have been optimized and iterated for 25 years, and European brands have cooperated for a long time

Equipment

Applications

The Cold Rolled Steel Bar Making Machine is used to produce high-strength ribbed steel bars for reinforced concrete applications in construction, bridges, tunnels, and infrastructure projects.

Global Cases

FAQ

1. Can this machine transform ordinary SAE1008/Q235 wire rods into high-strength construction rebar?

Absolutely. Our cold-rolling process induces work hardening in low-carbon wire rods, elevating the yield strength to meet Grade 500 (500Mpa) or higher. This allows you to produce high-value ribbed rebar from standard, lower-cost raw materials, significantly increasing your profit margins in competitive construction markets.

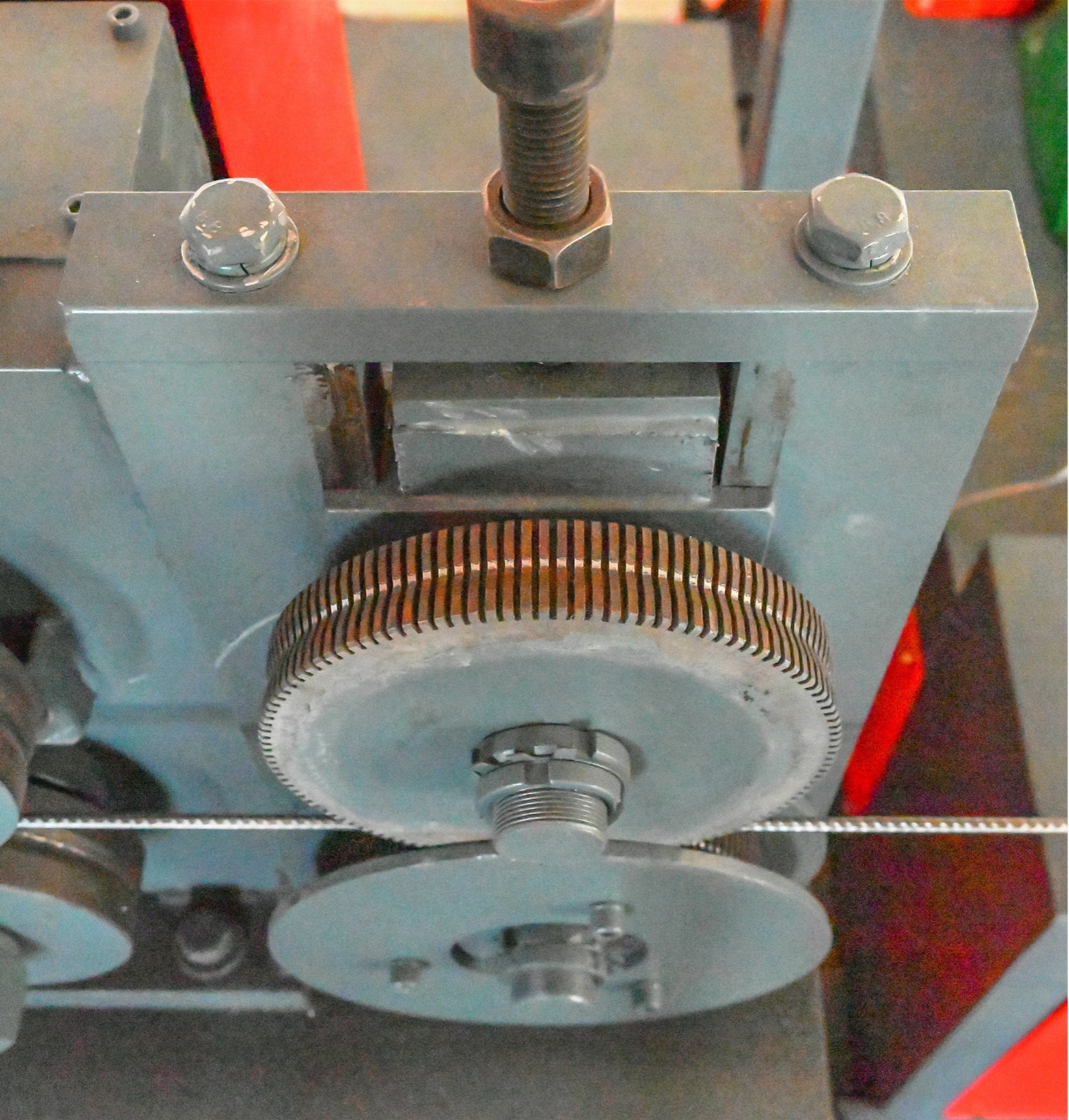

2. How does the machine ensure the ribs are consistent across the entire length of the coil?

We utilize a high-precision rolling cassette system with synchronized pressure adjustment. Combined with our Tungsten Carbide (TC) rolling rings, the rib height and spacing are maintained within a ±0.02mm tolerance, ensuring the finished bar complies with bonding strength requirements for reinforced concrete structures.

3. Does cold rolling make the steel too brittle for bending in construction?

No. Our machines are designed with a controlled reduction ratio across multiple passes. This ensures that while the strength increases, the steel retains sufficient elongation (ductility) to pass the 180° cold bend test required by most international building codes (e.g., BS4449 or ASTM).

4. What is the advantage of DAPU’s rolling rollers compared to standard steel rollers?

DAPU exclusively recommends and provides Tungsten Carbide (TC) rollers for our export models. TC rollers are nearly as hard as diamonds and heat-resistant, offering a lifespan 10 to 15 times longer than traditional alloy steel. This reduces the frequency of roller changes and ensures your machine maintains peak precision for hundreds of tons of production.

5. How does the lubrication system protect the machine during 24/7 high-speed production?

The machine is equipped with a centralized forced-lubrication system and an independent cooling circuit for the rolling stands. This prevents thermal expansion of the rollers and bearings, allowing the machine to run at speeds up to 120-150m/min without sacrificing the structural integrity of the internal gears or drive shafts.

6. How much labor is required to operate a full cold-rolling and take-up line?

Thanks to our integrated PLC automation, the entire line—from the raw wire decoiler to the finished coil take-up—requires only one skilled operator. This high level of automation drastically reduces labor overhead, which is a critical factor for manufacturers in regions like Southeast Asia, Latin America, and the Middle East.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.