Pulley Wire Drawing Machine

DAPU Pulley Wire Drawing Machine: The Reliable Foundation for High-Volume Wire Production. Engineered for continuous industrial output, this robust line transforms raw wire rods into high-quality fine wire with exceptional tensile consistency. Featuring heavy-duty cast-iron drums and a high-torque cooling system, it ensures stable processing of high/low carbon and galvanized steel. With its simplified mechanical design and low energy consumption, DAPU provides the most cost-effective solution for manufacturing nails, mesh, and construction wire. Invest in a 24/7 workhorse—scale your wire production with maximum durability and minimum overhead.

Key words:

Classification:

Product Description

|

| Description: |

DSLW1-5/550 simple pulley wire drawing machine is made up of main reducer motor, mould case, guiding wheel frame and general electrical motor control system. Each pot has reducer motor. It was drived by gears, are capacable of drawing rod wires of low-carbon steel, copper, aluminium etc. With electrical control, this machine is safety in operation, low noise and high efficiency.

It is widely applied to the manufacturing of standard parts (e.g. welding rod, wire nail, screw, etc), lead, wire rope, spring etc.

| Machine Display: |

| Technical Parameter: |

| Model | DSLW-1-5/550 |

| Strength tensile | mpa≥110kg/mm2 |

| Max. inlet Dia. | 6.5mm |

| Mini. outlet Dia. | 2.0mm |

| Drawing path | 1-9 (One 4+One 5) |

| Pot Dia. | 550 |

| Capacity | 207m/min |

| Total compress | 78--88.5% |

| Unit motor | 48kw+37.5Kw |

| Unit weight | 4500kg |

| Overall size | 5050×1105×1850mm |

| Auxiliary Equipment: |

|

|

|

| Fixed wire frame | Welding machine | Simple sheller |

|

|

|

| Wire coils | Tip roller | Drawing mould |

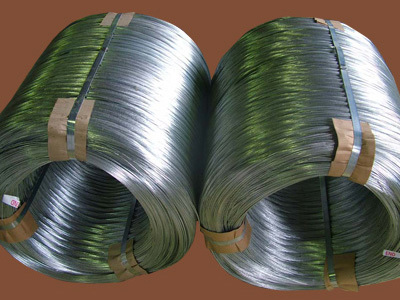

| Finished products & Application: |

It is widely applied to the manufacturing of standard parts (e.g. welding rod, wire nail, screw, etc), lead, wire rope, spring etc.

|

|

|

|

FAQ

1. What range of wire diameters can be processed with this pulley-type line?

Our pulley lines are modular and highly adaptable. Depending on the number of blocks, you can reduce wire rods from 6.5mm down to 1.0mm. By adding or removing drawing units, you can customize the final diameter to meet specific requirements for nail making, mesh weaving, or binding wire production.

2. How does the machine handle the heat generated during the high-speed drawing process?

To prevent wire brittleness and extend die life, each drawing drum is equipped with an internal water-cooling system and an external air-cooling fan. This dual-cooling mechanism effectively dissipates heat from both the drum and the wire, ensuring the finished product maintains its required mechanical properties and surface finish.

3. Is the machine compatible with high-carbon steel and stainless steel wires?

Yes. While primarily used for low-carbon steel, our heavy-duty models feature hardened Tungsten Carbide-coated drums and reinforced gearboxes to handle the higher resistance of high-carbon or alloy steel. This ensures the machine remains stable without excessive wear under high-torque conditions.

4. How does the pulley system ensure the wire doesn't break during the reduction stages?

The machine utilizes a self-adjusting pulley tension system. This design allows for slight speed variations between the blocks, preventing excessive tension or "necking" of the wire. Combined with our precision drawing dies, it ensures a smooth reduction ratio across all stages, significantly reducing the wire-breakage rate.

5. What is the maintenance requirement for a pulley-type machine in a dusty environment?

The Pulley Wire Drawing Machine is famous for its low-maintenance design. Unlike complex direct-drive lines, its purely mechanical transmission and heavy-duty bearings are built for harsh environments. Regular lubrication of the gears and cleaning of the water-cooling pipes are all that’s needed to keep it running for decades.

6. Can one operator manage the entire multi-block drawing line?

Absolutely. The line is controlled via a centralized console. Once the wire is threaded through the dies, the fully automated synchronization takes over. One operator can easily supervise the entire process, including the final take-up onto spools or coils, making it an extremely labor-efficient solution.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.