High-Speed Pulley Wire Drawing Machine

DAPU High-Speed Pulley Wire Drawing Machine: Industrial-Scale Output with Unmatched Stability. Engineered for high-volume wire processing, this line combines heavy-duty mechanical reliability with advanced frequency control for seamless, high-speed reduction. Optimized for low-carbon, high-carbon, and galvanized steel, it features an intensified dual water & air cooling system to preserve wire integrity at peak velocities. With its robust transmission and energy-efficient design, DAPU offers the perfect balance of massive tonnage and low maintenance. Accelerate your production—deliver premium wire at the industry's most competitive cost.

Key words:

Classification:

Product Description

|

| Description: |

DLW1-6/560 pulley wire drawing machine is made up of main reducer gear box, mould case, guiding wheel frame and electrical inverter control system. Each pot has JZT series or Y series motor and its own gear combination axis. According to reducer gear box, the drawing pot is vertical for working. It can be used in drawing metal wires made of steel, aluminum, copper, etc. Upon operating, it can complete the drawing procedures with machine set according to the specifications at once, from feeding to finished product. The speed of the gear roll is increasing in sequence along with the thinning and lengthening of the wire rods. It is widely applied to the manufacturing of standard parts (e.g. welding rod, wire nail, screw, etc), lead, wire rope, spring etc.

The machine has complete electrical system, perfect protection system and water seal cooling system, featured by easy combination, high productivity and convenient operation and management.

| Technical Parameter: |

| Model | DLW-1-6/560 |

| Strength tensile | mpa≥110kg/mm2 |

| Max. inlet Dia. | 6.5mm |

| Mini. outlet Dia. | 2.0mm |

| Drawing path | 1-6 |

| Pot Dia. | 560 |

| Capacity | 245m/min |

| Total compress | 78--88.5% |

| Equal compress | 30% |

| Inverter | FUTISTONE |

| Unit motor | 18.5kw |

| Unit weight | 1600kg |

| Overall size | 1700×1150×1750mm |

| Auxiliary Equipment: |

|

|

|

|

| Butt-welding machine | Tip roller | Descaling machine | Discharging wire machine |

|

|

|

|

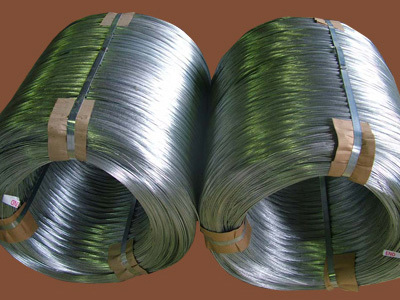

| Fixed wire frame | Wire coils | Drawing mould |

| Finished products & Application: |

It is widely applied to the manufacturing of standard parts (e.g. welding rod, wire nail, screw, etc), lead, wire rope, spring etc.

|

|

|

|

| Video: |

Click to view the video of the products

FAQ

1. How does the "High-Speed" model differ from standard pulley drawing machines?

Our High-Speed series integrates Inverter (VFD) technology and reinforced gearboxes, allowing for linear speeds up to 10-12m/s. This significantly increases daily tonnage compared to traditional fixed-speed models. It also features a smoother start/stop cycle, which reduces mechanical shock and prevents wire breakage during high-speed transitions.

2. What cooling technology is used to prevent wire brittleness at high speeds?

At high speeds, heat is the enemy. We use an internal narrow-slit water cooling system inside the drums combined with high-pressure air fans. This ensure the heat generated by friction is dissipated instantly, keeping the wire temperature below critical levels to maintain its ductility and ensure a bright, smooth surface finish.

3. Can this machine handle high-tensile wire rods for spring or PC wire production?

Yes. The drums are treated with Tungsten Carbide spray-coating (hardness up to HRC 60+), making them extremely wear-resistant. Combined with a high-torque motor and heavy-duty V-belt or gearbox transmission, the machine provides the necessary power to draw high-carbon and alloy steels without slippage or motor strain.

4. How does the machine ensure consistent wire diameter across thousands of meters?

Precision starts with the Die Box design. Our boxes are designed for both lubricant powder and optional water cooling. By maintaining a constant temperature at the die and using a synchronized PLC system to control drum speeds, we ensure a diameter tolerance of ±0.01mm, meeting the strictest international standards for downstream processing.

5. Is the machine equipped with safety features for high-speed industrial operation?

Safety is paramount. The machine includes protective wire-mesh covers, emergency stop buttons on every block, and automatic wire-breakage sensors. If the wire snaps or a tangle is detected, the entire line performs a controlled emergency stop within seconds to prevent operator injury or equipment damage.

6. What is the typical energy saving compared to older generation drawing lines?

By utilizing high-efficiency motors and VFD (Variable Frequency Drive) technology, our high-speed lines can reduce electricity consumption by 15-25% per ton of wire. Additionally, the optimized transmission system minimizes friction loss, directly contributing to lower operational overhead and a faster ROI.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.