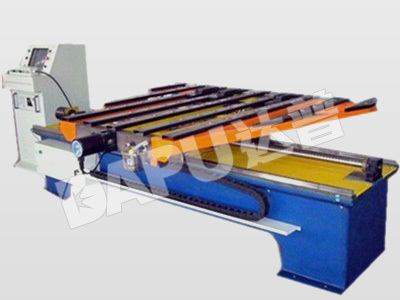

Sheet Metal Perforation Machine

Key words:

Classification:

Product Description

| Description: |

DAPU Sheet Metal Perforation Machine – Key Features

Heavy-Duty Steel Welded Frame

Built for stability and long-term reliability, even under high-load production demands.

Top-Brand Main Motor (SIEMENS)

Ensures consistent performance and long-lasting power with minimal downtime.

Dry Pneumatic Clutch & Brake System

Fast response and precise control for high-speed, continuous operations.

Oil-Immersed Gear Transmission

Enhances durability and reduces maintenance by minimizing wear on moving parts.

Reinforced Multi-Face Slide Guides

Six-face guide rails (eight-face for JH21-315B/400B models) provide superior slide stability and accuracy.

Hydraulic Overload Protection

Automatically halts operation during overloads to protect both the press and tooling.

User-Friendly Die Height Adjustment

Manual adjustment with scale on JH21-16/25/45 models.

Electric adjustment with digital display on JH21-63 and larger models.

JH21-45 offers optional electric adjustment with numeric display.

Balanced Cylinder Lift System

Ensures smooth press motion and energy balance (not included in JH21-16 model).

Dual Lubrication System

Electrical grease lubrication for main parts.

Manual lubrication for the balance cylinder for easy upkeep.

Integrated PLC Control System

Powered by global brands, offering reliable automation and expansion-ready interface with electronic cam.

Premium Electrical Components

All buttons, switches, circuit breakers, and pneumatic valves are sourced from trusted international brands.

Flexible Automation & Safety Options

Optional configurations include:

Wet clutch system

Air cushion

Automatic feeding shaft

Light curtain safety system

Slide knockout unit

Auto-eject and automation-ready features

| Technical Parameter: |

| Specifications | JH21-16 | JH21-25B | JH21-45 | JH21-63 | JH21-80 | JH21-100 |

| Nominal force (kn) | 160 | 250 | 450 | 630 | 800 | 1100 |

| Stroke under nominal force (mm) | 2 | 3 | 4 | 4 | 5 | 6 |

| Slide block stroke (mm) | 60 | 60 | 100 | 120 | 140 | 160 |

| Number of stroke (min-1) | 135 | 100 | 80 | 70 | 60 | 50 |

| Max die set height (mm) | 220 | 200 | 270 | 300 | 320 | 350 |

| die set height adjustment (mm) | 30 | 50 | 60 | 80 | 80 | 80 |

| Between slide center and frame (mm) | 160 | 160 | 230 | 300 | 300 | 350 |

| Worktable dimensions (F.B*LR)mm | 310×700 | 300×680 | 440×810 | 580×900 | 580×1000 | 680×1150 |

| Shank hole(DiaxDepth)(mm) | Φ40*Φ60 | Φ40*Φ60 | Φ40*Φ60 | Φ50*Φ80 | Φ50*Φ80 | Φ60*Φ80 |

| Thickness of bolster (mm) | 65 | 70 | 110 | 110 | 120 | 140 |

| Dimensions of slide bottom surface (F.B*L.R)mm | 250×320 | 270×330 | 340×410 | 400×480 | 420×560 | 500×650 |

| Distance between columns of body | 460 | 448 | 550 | 560 | 640 | 760 |

| Motor power (kw) | 3 | 3 | 5.5 | 5.5 | 7.5 | 11 |

| Outline dimension (F.B*L.R*H)mm | 1500×1040×2000 | 1350×980×2130 | 1390×1125×2275 | 1580×1250×2580 | 1640×1290×2800 | 1850×1450×3060 |

| Numerical Control Desk |

Numerical Control Desk | 1. Suitable for punching machine times: 35---120 times per minute; 2. Feeding fix accuracy: ±0.15mm; 3. Mini programme unit: 0.01mm 4. Max. feeding material speed: 24m/minute 5. Processing Specification: 2500mmX1250mm 6. Linear sliding bearing of down: 35X3000, up 35X1580 7. Ball-and-Screw unit of down: 4020X2875, up 3220X1644 8. Motor: 130-202 80--120v 0.9° 36--38 n/m 9. Motor: 110-204 80--120v 0.75° 20--24 n/m |

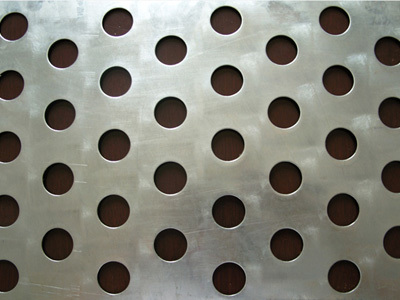

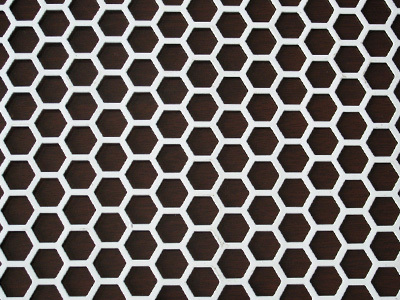

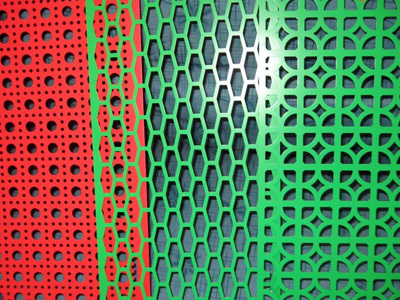

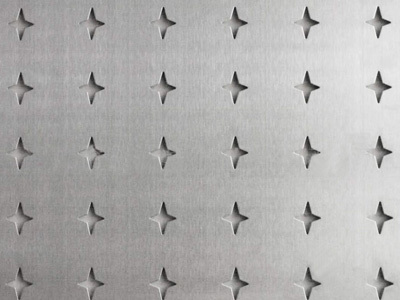

| Finished Product & Application: |

|  |  |  |

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.