Rolling whee: Rolling wheel material: Tungsten carbide;Service life: around 2000T

High Speed Cold Rolling Ribbed Steel Bar Production Line

The High-Speed Cold Rolling Ribbed Steel Bar Machine efficiently transforms low carbon steel wire rods into high-tensile ribbed bars through precision cold rolling and ribbing. Equipped with automated feeding, servo control, and a PLC system, it ensures consistent bar size, strong rib formation, and stable high-speed output. The machine uses wear-resistant rollers, a water-cooled system, and low-maintenance components to guarantee long service life and reliable performance for continuous production.

Key words:

Classification:

Product Description

Description

This production line mainly rolls diameter of 6—14mm and ordinary low carbon tray bar or low alloy tray bar with multiple cold rolling and a ribbing rolling, which finally forms reinforcing steel with three-side crescent shape ribs. It's widely applicable to highway, airport, irrigation works, city planning and construction engineering.

Technical Parameter

| Model | LZ-60000T |

| Inlet wire diameter | 5.5–14 mm |

| Outlet wire diameter | 5–13 mm (rebar) |

| Drawing motor | 90 kW × 2 |

| Coiling motor | 45 kW × 1 |

| Gearbox type | Hardened reducer |

| Production speed | Max. 300–350 m/min |

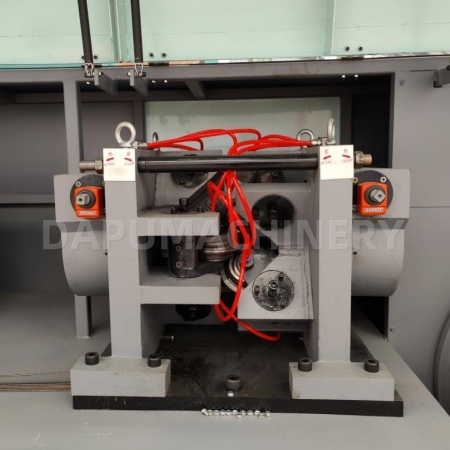

| Rolling mill | 2 sets (European design), water-cooled Use 1 or 2 depending on diameter reduction |

| Drawing drum | Tungsten carbide spraying on drum surface |

| Rolling mill material | Main structure: No.45 steel precision casting Turbine: 40Cr material Double-hole shaft: 40Cr material Wheel assembly: Bearing steel Rolling wheel: Tungsten carbide |

Video

Features / Benefits

Intelligent CNC System for High-Efficiency Operation

The Cold Rolling Steel Bar Ribbed Production Line – High Speed is equipped with a state-of-the-art PLC control module and a 10.1-inch industrial touch screen. This enables fully automated CNC operation across the entire production process. With one-key parameter presetting (including thread pitch and diameter adjustment), the system greatly reduces manual errors. Operators can become proficient after just 4 hours of training, streamlining workforce adaptation and productivity.

Energy-Efficient Variable Frequency Drive

Designed for optimal energy savings, the Cold Rolling Steel Bar Ribbed Production Line – High Speed features dual 90kW drawing motors and a 45kW coiling motor, all driven by advanced variable frequency technology. The system automatically adjusts speed and power consumption based on the inlet wire diameter (5.5–14 mm), saving over 30% more energy compared to conventional systems.

Military-Grade Compact Transmission Structure

The Cold Rolling Steel Bar Ribbed Production Line – High Speed uses a modular compact design that saves 25% more space compared to similar products. It is engineered with premium components:

Hardened Gearbox Reducer for high torque and long service life

Drawing Drum coated with tungsten carbide for superior wear resistance

Main Rolling Mill: Two sets of European-design water-cooled rolling mills (adjustable based on diameter reduction needs)

Rolling Mill Construction:

Main frame: No.45 steel precision casting

Turbine: 40Cr alloy steel

Double-hole shaft: 40Cr

Wheel assembly: Bearing steel

Rolling wheels: Tungsten carbide for maximum durability

With a maximum production speed of 300–350 m/min, this line offers both speed and performance for large-volume operations.

Electric Parts

Core electrical components have been optimized and iterated for 25 years, and European brands have cooperated for a long time

Equipment

Applications

The Cold Rolling Steel Bar Ribbed Production Line – High Speed is widely used for producing high-strength ribbed steel bars for reinforced concrete structures in construction and infrastructure projects.

Global Cases

FAQ

1. How much can this machine improve the tensile strength of the raw wire rod?

By utilizing cold-rolling technology, the machine increases the tensile strength of low-carbon steel (e.g., Q235/SAE1008) by 20% to 40%. This transformation allows ordinary wire rods to meet high-strength standards such as HRB400, HRB500, or equivalent international building codes, significantly reducing the total steel required in construction.

2. Does the rib pattern produced meet international standards for concrete bonding?

Yes. Our precision rolling cassettes produce a standard three-sided or two-sided crescent rib pattern. These ribs are designed to maximize the mechanical interlocking between the steel bar and the concrete, meeting standards like ASTM A615 and ISO 6935-2, which is critical for high-rise and infrastructure safety.

3. What is the material of the rolling rollers, and what is their estimated service life?

We use Tungsten Carbide (TC) for the core rolling rings. Unlike traditional alloy steel rollers, TC rings offer extreme hardness and heat resistance. Depending on the material hardness, one set of rollers can process 800 to 1,200 tons of steel before requiring maintenance, ensuring consistent rib height and diameter throughout the production cycle.

4. How does the machine ensure the "Hooked-end" angle is precise for maximum bonding?

The DAPU Steel Fiber Machine features a multi-stage cold-forming process. The hook angle and length are mechanically locked by precision-ground molds. This ensures that every fiber provides the maximum mechanical anchorage within the concrete matrix, preventing pull-out and enhancing the structural integrity of the pavement or lining.

5. Is this machine energy-efficient for factories with high electricity costs?

Yes. Our latest models utilize Variable Frequency Drive (VFD) technology and high-efficiency gearboxes. This setup reduces energy consumption by 15%–20% compared to traditional direct-start machines. Additionally, the optimized mechanical transmission minimizes power loss during the high-torque rolling process.

6. What is the level of automation, and how many workers are needed to run the line?

The entire line, from decoiling to rolling and final take-up/cutting, is fully automated. A single operator can manage the entire production line via the central control console. The system includes automatic sensors for wire-breaks and motor overloads, ensuring safe operation with minimal human intervention.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.