CS-B Barbed Wire Machine

Secure your market share with the most reliable solution for high-volume security and agricultural fencing. The DAPU Barbed Wire Machine is engineered to transform galvanized or PVC-coated wire into high-quality double-strand or single-strand barbed wire with unmatched speed and precision. Designed for maximum uptime, our machine features a synchronized twisting system that ensures the barbs are consistently spaced and locked tight to prevent sliding. Whether you are supplying military borders, industrial sites, or large-scale ranches, DAPU provides the lowest energy consumption per ton and a user-friendly design that allows one operator to manage multiple lines. Stop losing margins to inefficient manual production—upgrade to DAPU and deliver the most trusted fencing in the world.

Key words:

Classification:

Product Description

|

| Description: |

This machine can produce single twisted barbed wire which is widely used in national defense, military, railway, highway, agriculture, animal husbandry and other industries. The materials of barbed wire usually hot dipped galvanized wire, electric galvanized wire etc.

The advantage of this machine: saving materials

| Technical Parameter: |

| Motor power | 2.2kw |

| Raw material | Galvanized wire |

| Unit wire diameter | 1.4mm-3.0mm |

| Barbed wire diameter | 1.4mm-2.8mm |

| Barbed space | 4″,5″ |

| Theoretical production | 50-100kg/h, 18m/min |

| Total weight | 1000kg |

| Production depends on the wire diameter. Special specification models can be customized according to the customer’s requirement. |

|

| Finished Products & Application: |

It is widely used in national defense, military, railway, highway, agriculture, animal husbandry and other industries.

| Video: |

| Finished Products & Applications: |

Chain link Fence is extensively used as fences for playground and gardens, highway, railway, airport, port, residence, etc.

|

|

| Related Products: |

|

|

|

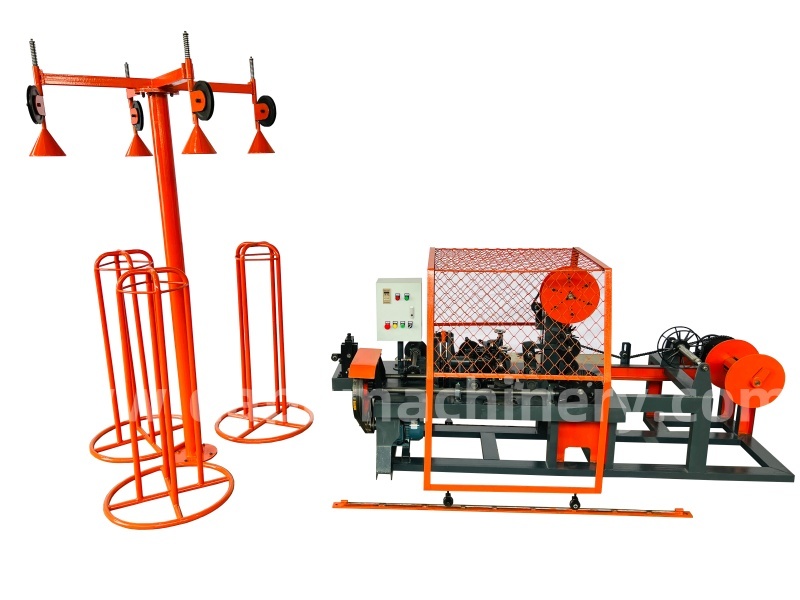

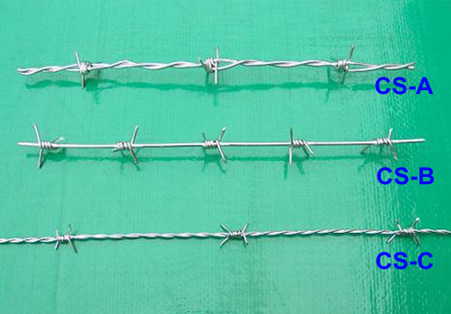

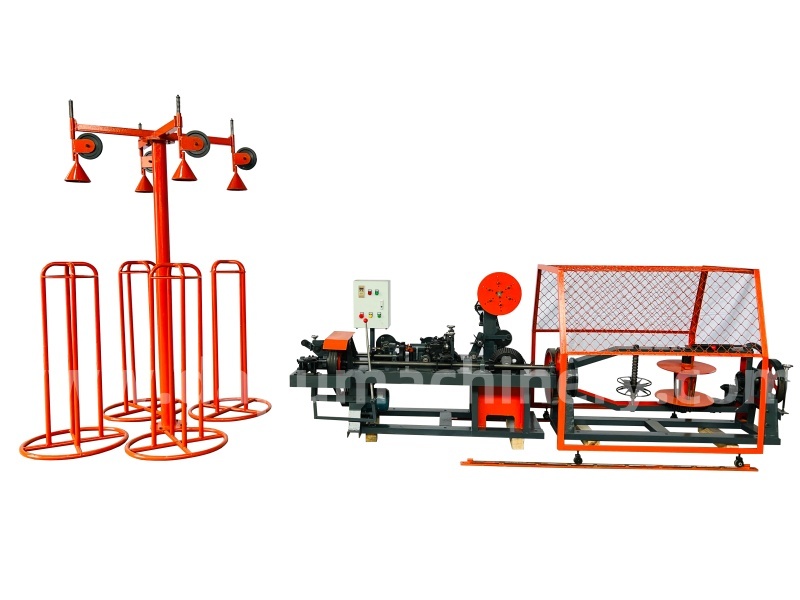

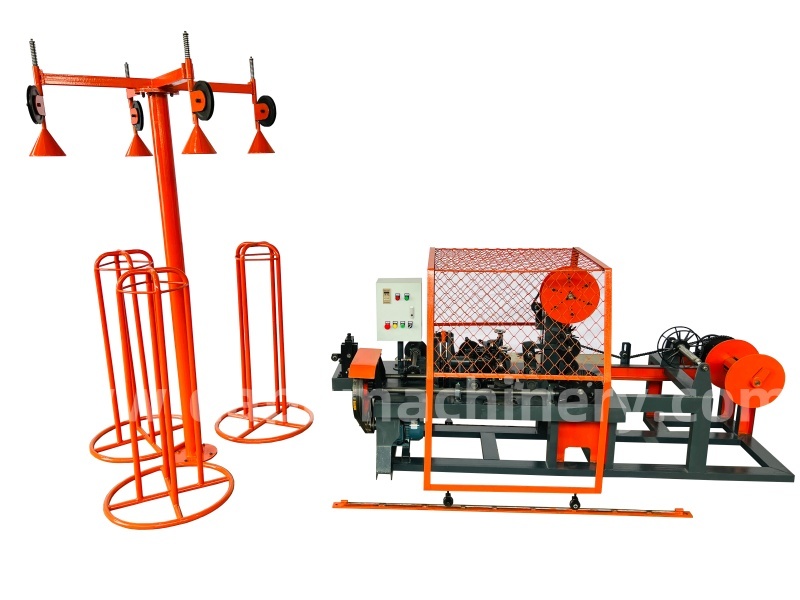

| CS-A Barbed Wire Machine | CS-B Barbed Wire Machine | CS-C Barbed Wire Machine |

FAQ

1. Can this machine produce both traditional Double-Twist and Reverse-Twist barbed wire?

We offer specific models for different market preferences. Our CS-A series is optimized for traditional Double-Twist (common in India and SE Asia), while our CS-C series is a high-speed specialist for Reverse-Twist (Standard in the US and Europe). Reverse-twisting ensures the wire doesn't tangle and the barbs stay perfectly upright for maximum deterrence.

2. What wire materials can be used, and does the machine protect the zinc coating?

Our machines are compatible with Hot-dipped Galvanized (High/Low Zinc), Electro-galvanized, and PVC-coated wire. We use polished alloy steel guiding rollers and precision-engineered feeding nozzles to ensure the anti-corrosion layer is not scratched or peeled during the twisting process, extending the fence's life in humid environments.

3. How do you ensure the barbs are locked tightly and won't slide along the strand?

Stability is achieved through our synchronized mechanical feeding system. The barb wire is wrapped around the strand wire with a high-torque mechanical finger that "bites" into the twist. This ensures that even under manual pressure or livestock impact, the barbs remain at their pre-set intervals (3", 4", or 5") without shifting.

4. What is the production output per 8-hour shift?

Our high-speed models can produce approximately 400-600 kg of finished barbed wire per 8-hour shift, depending on the wire diameter and barb spacing. Because the line is fully automated with wire-break sensors, a single operator can manage 3 to 4 machines simultaneously, significantly lowering your labor overhead.

5. Does the machine include an automatic coiling system for finished rolls?

Yes. Every DAPU Barbed Wire Machine comes with an integrated automatic take-up unit. It winds the finished wire into neat, uniform coils (typically 25kg or 50kg) and includes a tension control system to ensure the rolls are tight and easy to handle for the end-user.

6. How difficult is it to maintain the machine in remote or dusty areas?

We’ve designed the machine with a heavy-duty cast-iron frame to minimize vibration and wear. All key gears are enclosed in an oil bath or equipped with easy-access lubrication points. This "simple but robust" engineering makes it ideal for factories in developing regions where high-tech maintenance support might be limited.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.