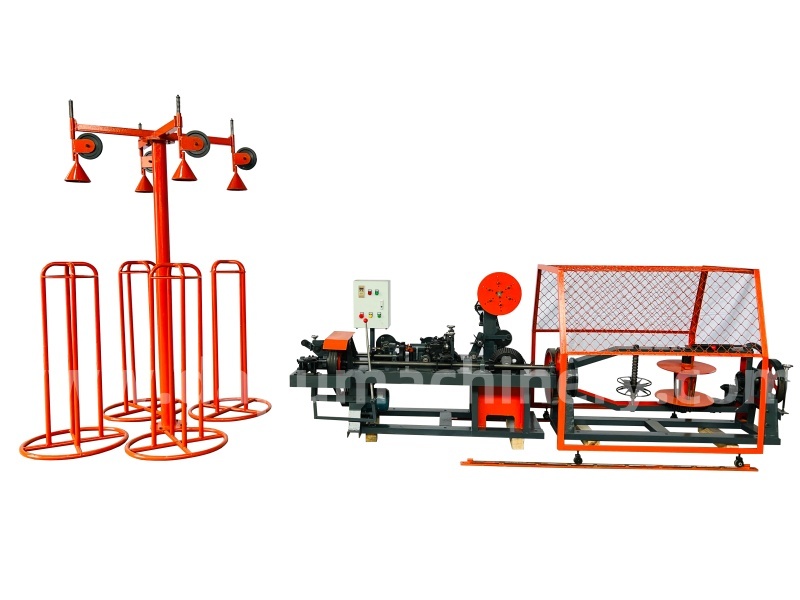

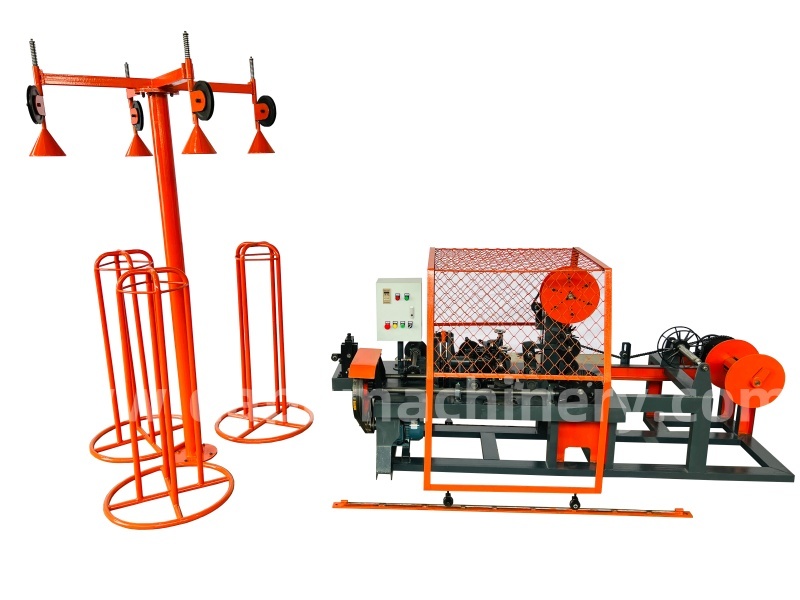

CS-C Barbed Wire Machine Positive and Negative Twist

Step into the high-end fencing market with the CS-C, DAPU’s flagship machine for Reverse-Twist barbed wire production. Unlike conventional models, its advanced bi-directional twisting system eliminates internal wire tension, producing a perfectly flat, high-tensile product that won’t coil or tangle—exactly what professional contractors and government agencies demand. Engineered for nearly double the speed of standard machines with whisper-quiet operation, the CS-C also safeguards heavy zinc and PVC coatings through precision components, maximizing field longevity. Ideal for large-scale tenders and premium export markets, the CS-C delivers higher tonnage, superior quality, and faster ROI—your ultimate competitive edge in barbed wire manufacturing.

Key words:

Classification:

Product Description

|

| Description: |

This machine can produce positive and negative twisted barbed wire which is widely used in national defense, military, railway, highway, animal husbandry and other industries. The materials used for positive and negative twisted barbed wire are usually hot dipped galvanized wire, electric galvanized wire etc.

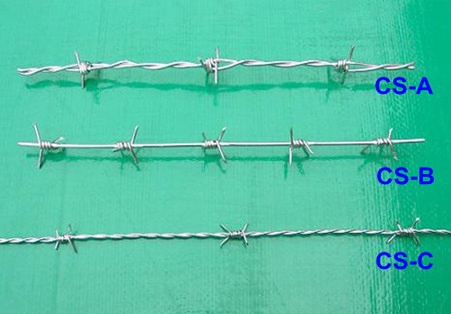

Positive and negative twisted barbed wire use positive and negative way for winding flowers, the barbed wire products produced has no rebound and winding phenomenon, so it is more beautiful compared with the general barbed wire.

| Technical Parameter: |

| Motor power | 2.2kw |

| Raw material | Galvanized wire |

| Unit wire diameter | 1.4mm-2.8mm |

| Barbed wire diameter | 1.4mm-2.8mm |

| Barbed space | 3″,6″,5″or4″,5″,6″ |

| Twisted number | 7 |

| Theoretical production | 40kg/h |

| Total weight | 1000kg |

| Barbed space, twisted number can be customized according to the customer’s request. We can customize according to the customer’s request. |

|

| Finished Products & Application: |

It is widely used in national defense, military, railway, highway, animal husbandry and other industries.

| Video: |

| Finished Products & Applications: |

Chain link Fence is extensively used as fences for playground and gardens, highway, railway, airport, port, residence, etc.

|

|

| Related Products: |

|

|

|

| CS-A Barbed Wire Machine | CS-B Barbed Wire Machine | CS-C Barbed Wire Machine |

FAQ

1. What are the technical advantages of "Reverse-Twist" produced by the CS-C?

Reverse-twist technology alternates the direction of the wire twist. This neutralizes the torque, meaning the barbed wire will stay completely flat when unrolled. It is safer to install, doesn't kink, and allows for the use of high-tensile wire, which is lighter yet stronger than traditional low-carbon wire.

2. How much faster is the CS-C compared to the traditional CS-A model?

The CS-C is built for high-volume industrial output. It can achieve production speeds of up to 450-500 meters per hour (approx. 25-30 rolls per shift). The refined mechanical balance allows it to run at higher RPMs with lower vibration and noise, significantly increasing your daily tonnage.

3. Can the CS-C handle high-tensile wire (up to 1200MPa) for premium fencing?

Yes. The CS-C is specifically reinforced to handle high-tensile steel wire. This allows you to produce the "American Style" or "European Standard" barbed wire, which uses thinner, high-strength wire to achieve the same breaking load as thicker soft wire, effectively saving you 20-30% in raw material costs.

4. Does the CS-C feature an automatic stop system for wire breaks or tangles?

Absolutely. To protect the precision gears and minimize waste, the CS-C is equipped with sensitive electronic sensors. If the strand wire breaks or a coil becomes tangled, the machine triggers an instant emergency stop, allowing the operator to fix the issue without damaging the tooling.

5. How does the machine ensure the barbs are consistently sharp and uniform?

The CS-C uses a dual-stage barb feeding and cutting system made from high-grade SKD11 alloy steel. The cutting angle is precisely fixed to ensure every barb is razor-sharp. The mechanical timing is locked via a heavy-duty camshaft, ensuring the barb spacing (e.g., 4" or 5") never varies by more than ±2mm.

6. What is the level of automation for the final coiling process?

The machine includes a fully synchronized automatic take-up unit. It features a variable-speed friction clutch that maintains perfect tension as the roll grows in diameter. This ensures every 25kg or 50kg roll is perfectly cylindrical and compact, which is vital for professional branding and maximizing container loading space.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.