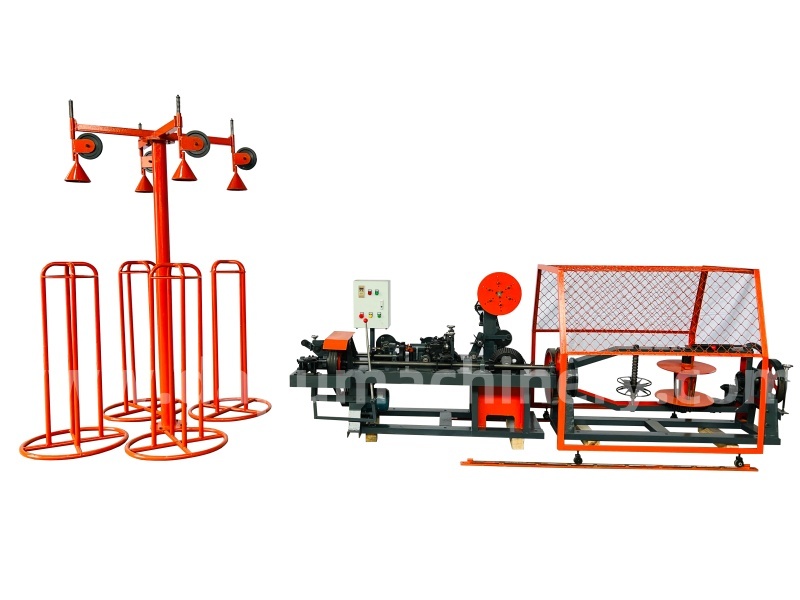

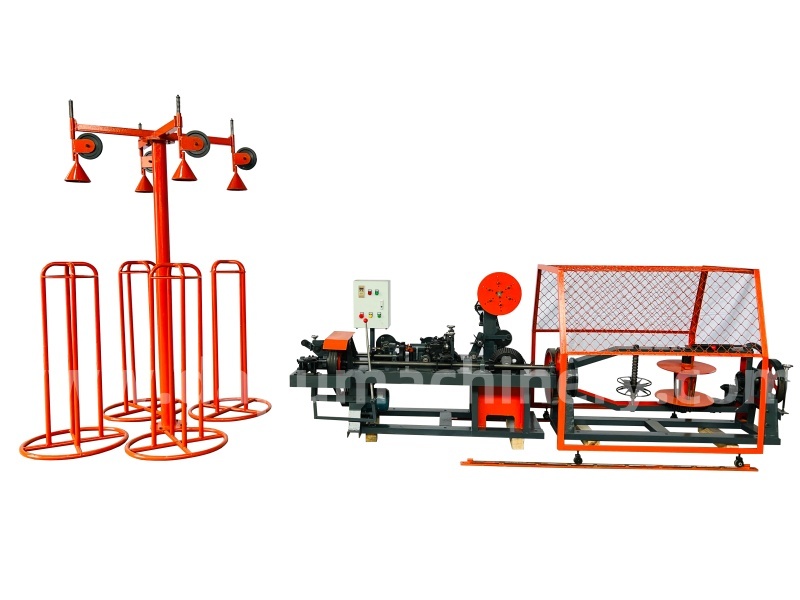

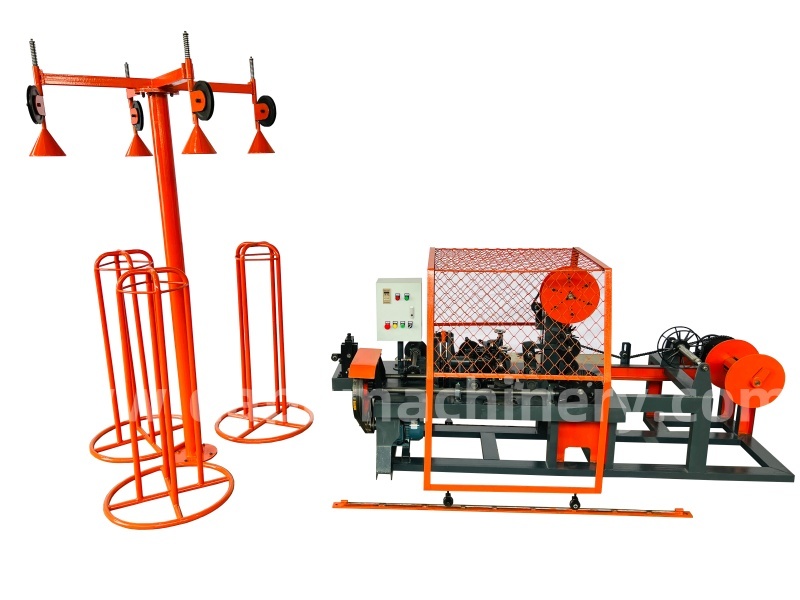

CS-A Barbed Wire Machine

The CS-A is the industry standard for producing high-quality double-strand, four-point barbed wire. Known as the "Workhorse" of the fencing industry, this machine is specifically engineered for manufacturers who prioritize simplicity, long-term durability, and a fast Return on Investment (ROI). Featuring a robust cast-iron frame and a synchronized mechanical drive, the CS-A processes hot-dipped galvanized and PVC-coated wire with ease. It is the perfect entry-to-mid-level solution for supplying agricultural ranches, military borders, and residential security projects. With its low power consumption and minimal maintenance requirements, the CS-A allows you to start high-volume production with low overhead and maximum reliability. Build your fencing empire on the foundation of DAPU’s most time-tested technology.

Key words:

Classification:

Product Description

|

| Description: |

This machine can produce general barbed wire also called double twisted barbed wire which is widely used in national defense, railway, highway, agriculture, animal husbandry and other industries. The materials of barbed wire usually hot dipped galvanized wire, electric galvanized wire and PVC coated wire etc.

The advantage of this machine: high quality and inexpensive

| Technical Parameter: |

| Motor power | 2.2kw |

| Raw material | Galvanized wire or PVC-coated wire |

| Wire diameter | 1.4mm-3.0mm |

| Barbed wire diameter | 1.4mm-2.8mm |

| Barbed space | 76mm (3") / 102mm (4") / 127mmm(5") |

| Twisted number | 3-5 |

| Theoretical production | 70-150kg/h, 25m/min |

| Total weight | 1200kg |

| Remind: We can customized according to the customers’ request. Twisted number and barbed space can be customized according to the customer’s request. |

|

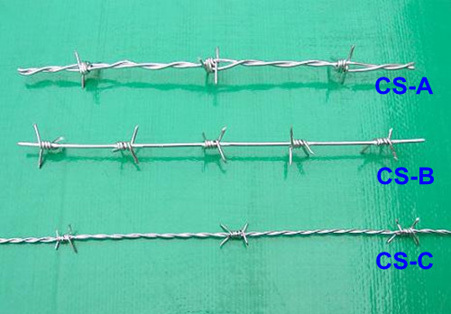

| Finished Products & Application: |

It is widely used in national defense, railway, highway, agriculture, animal husbandry and other industries.

| Video: |

| Finished Products & Applications: |

Chain link Fence is extensively used as fences for playground and gardens, highway, railway, airport, port, residence, etc.

|

|

| Related Products: |

|

|

|

| CS-A Barbed Wire Machine | CS-B Barbed Wire Machine | CS-C Barbed Wire Machine |

FAQ

1. Why is the CS-A considered the best "entry-level" investment for new factories?

The CS-A features a purely mechanical transmission system, which means it doesn't require complex electronic programming or high-end engineers to operate. Its low initial cost and high resale value make it the safest investment for businesses in Latin America, Africa, and Southeast Asia looking to dominate the local fencing market.

2. What is the difference between the CS-A and the high-speed reverse-twist models?

The CS-A produces the traditional "positive twist" barbed wire, where the strand wires are twisted in a single direction. This structure is the most widely recognized and accepted in traditional agricultural markets. While it operates at a slightly slower speed than reverse-twist models, its mechanical stability and ease of repair are significantly higher.

3. Can the CS-A handle different barb spacings (e.g., 3 inches vs. 5 inches)?

Yes. The barb spacing can be easily adjusted by changing the mechanical gears (shifting gears). This allows you to produce dense barbs for high-security areas or wider-spaced barbs for cost-effective farm fencing, giving you the flexibility to meet diverse customer demands.

4. What are the requirements for the raw material wire used in the CS-A?

The CS-A is highly versatile and can process low-carbon galvanized wire (usually 2.0mm to 2.8mm). Because of its robust feeding mechanism, it can handle variations in wire quality that more complex machines might struggle with, making it ideal for regions where raw material consistency may vary.

5. How does the machine prevent the wire from tangling during the coiling process?

The CS-A is equipped with an integrated friction-plate take-up unit. This system automatically synchronizes the coiling speed with the twisting speed. It maintains constant tension on the wire, ensuring the finished rolls are tightly wound and uniform, which is essential for professional-looking products and efficient shipping.

6. What is the typical lifespan of the wear parts on the CS-A model?

The key wear parts (twisting fingers and cutting blades) are made of hardened alloy steel. Depending on the wire type, these parts can last for 3-6 months of continuous production before requiring sharpening or replacement. Due to the simple design, a set of replacement parts can be swapped out in less than 15 minutes.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.