Leveling, Slitting and Cutting Machine

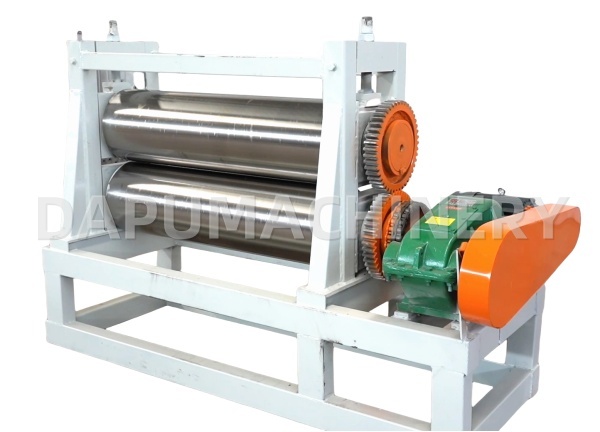

DP-160T Expanded Metal Mesh Machine

This is our specialized powerhouse, engineered for infrastructure and heavy industrial demands. Reliably process steel plate up to 6.0mm thickness with unmatched power and stability. Features a reinforced Gantry structure and SKD11 premium dies, guaranteeing zero vibration and superior mesh flatness. Minimize downtime and meet high-stress project standards. Invest in the ultimate durability and capacity for maximum productivity.

Key words:

Classification:

Product Description

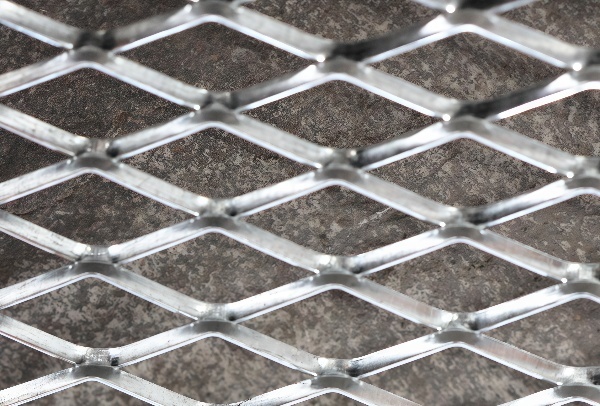

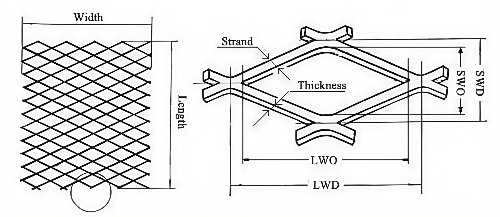

Expanded metal mesh machine can produce expanded metal mesh which is widely used in construction, hardware, window and door, machine protection etc. It can be produced width max.1200mm and thickness of metal sheet max.1.5mm. The material for expanded metal mesh can be low carbon steel plate, stainless steel plate, aluminum plate, copper plate and so on.

Technical Parameter

| Model | DP-160T | |

| Material thickness | 0.5-6mm | 0.5-5mm |

| Material max. width | 2000mm | 2500mm |

| LWD of mesh opening | 200mm | 200mm |

| Distance of feed | 0-10mm | 0-10mm |

| Speed (R/m) | 55 | 45 |

| Motor | 30/1470 | 30/1470 |

| Net weight | 16T | 20T |

Optional Equipment

Finished Product

It is widely used in construction, hardware, window and door, machine protection etc.

Order delivery

Other models

FAQ

What differentiates the DP-160T from the 100T, and what is its maximum material thickness capability?

The DP-160T represents our most powerful standard model, built for extreme loads. It features a significantly reinforced gantry structure, heavier main shaft, and robust gearbox. It is designed to reliably process steel plate up to 6.0 mm thickness for the most demanding applications.

2. How is the die durability maintained when processing high-strength or abrasion-resistant materials on the 160T?

For the 160T, we strictly utilize specialized SKD11/D2 grade tool steel for the dies, sometimes supplemented with TIN (Titanium Nitride) coating. This material choice ensures exceptional hardness and abrasion resistance, dramatically extending the die's life when cutting tough, thick materials.

3. What key safety features are integrated into the DP-160T due to its high operating force?

Safety is paramount. The 160T includes a full enclosure guard, dual-hand operation buttons to ensure operator distance, a pressure overload sensor linked to an emergency stop, and a locking pin mechanism for maintenance safety.

4. What is the typical speed/strokes per minute (SPM) when the 160T is processing 5.0mm thick sheet metal?

Given the high force required, the speed is optimized for stability. When processing 5.0mm material, the DP-160T typically operates at a reliable rate of 30 to 45 strokes per minute (SPM), maximizing cut quality and machine life rather than sacrificing them for marginally higher speed.

5. The 160T requires a powerful motor. How does DAPU optimize energy consumption for this model?

We utilize high-efficiency, frequency-controlled motors to ensure energy is only drawn when maximum force is needed. The flywheel stores kinetic energy, and the motor runs efficiently to maintain its speed, ensuring a good kW-to-Tonnage ratio to minimize electricity costs.

6. Does the 160T support customization for extra-wide mesh, such as up to 2.5 meters?

Yes, the DP-160T platform is often chosen for custom wide-span applications. We offer a special custom-built frame version of the 160T that can handle coil widths up to 2.5 meters, which is highly valued in large industrial building projects and highway guardrail fabrication.

Related recommend Products

Get free product quotes

We will contact you within one working day. Please pay attention to your email.